Simulation Integrated Design

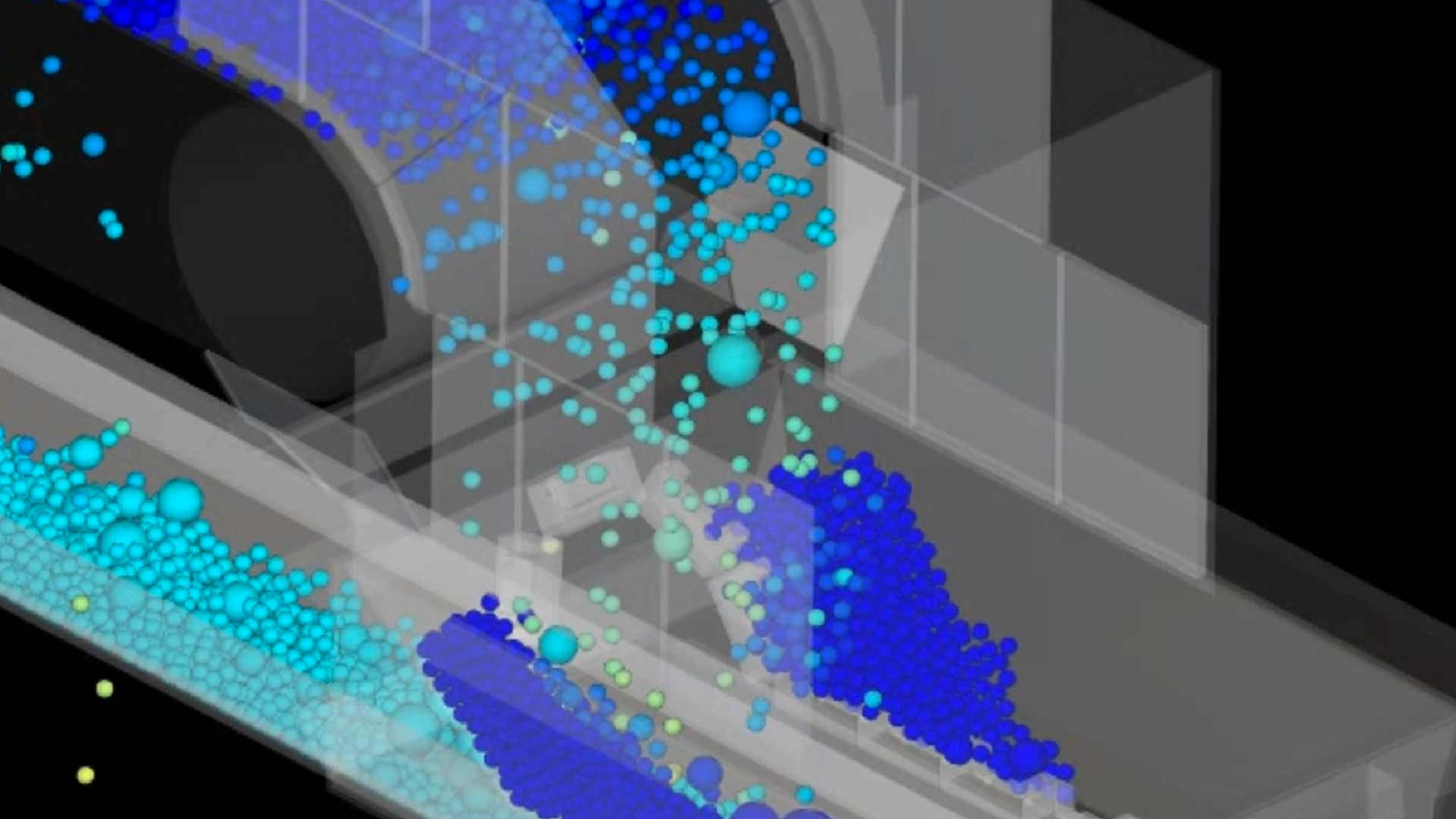

Computational simulation software is an effective way to enhance mining and metallurgical processes, compare design modifications, replicate changes to production or environmental conditions, estimate liner wear, improve mixing efficiency and more.

This is done by inputting realistic throughput variables of existing equipment into a CAD model. This could include particles, fluids and/or fibers to create coherent flow structures.

Wear Improvement Solutions Are What We Take Seriously

With more than 15 years of industrial related expertise and compliance with industry practice our clients can attain significant cost savings by slowing peak wear rate without compromising throughput.

CAD & DEM Processing

Through CAD and DEM processing we evaluate pre- and post-results when determining the ideal wear solution package for the individual applications as shown below:

- Chrome White Iron

- Ceramic

- Weld Overlay Plate

- Composite White Iron

- Quench and Tempered (Q&T)

Wear Improvement Strategy

IMS has extensive experience with various industry wear liners and their respective advantages and limitations. We provide our clients with unbiased and independent recommendations for optimal liner selection and preventive maintenance planning strategies. Historically we have delivered significant changes resulting in improved reliability, reduction in downtime and, more importantly, preventive maintenance planning costs.