D11R T Dozer Stands

D11R T Dozer Stands

D11R T Dozer Stands

Background

The previous method of supporting the Dozers when the blade and ripper shank are removed became unstable when changing out the dozer track final drives. An accident notice was raised due to the 08H93 Dozer falling from four positioned 55 tonne Caterpillar jacks. This fall occurred while rolling off the right side track. The track removal setup process was executed outside the safe working procedure.

Throughout the investigation, issues were raised and noted for change. It was evident that if this delicate process was conducted outside the boundaries, in terms of jack positions and operator and forklift driver coordination when physically removing the track, the risk of being out of sync will cause the forklift to pull the dozer off the jacks.

Background

The previous method of supporting the Dozers when the blade and ripper shank are removed became unstable when changing out the dozer track final drives. An accident notice was raised due to the 08H93 Dozer falling from four positioned 55 tonne Caterpillar jacks. This fall occurred while rolling off the right side track. The track removal setup process was executed outside the safe working procedure.

Throughout the investigation, issues were raised and noted for change. It was evident that if this delicate process was conducted outside the boundaries, in terms of jack positions and operator and forklift driver coordination when physically removing the track, the risk of being out of sync will cause the forklift to pull the dozer off the jacks.

Background

The previous method of supporting the Dozers when the blade and ripper shank are removed became unstable when changing out the dozer track final drives. An accident notice was raised due to the 08H93 Dozer falling from four positioned 55 tonne Caterpillar jacks. This fall occurred while rolling off the right side track. The track removal setup process was executed outside the safe working procedure.

Throughout the investigation, issues were raised and noted for change. It was evident that if this delicate process was conducted outside the boundaries, in terms of jack positions and operator and forklift driver coordination when physically removing the track, the risk of being out of sync will cause the forklift to pull the dozer off the jacks.

08H93 Dozer - side view

Alternative view

08H93 Dozer - side view

Alternative view

08H93 Dozer - side view

Alternative view

Scope of Work

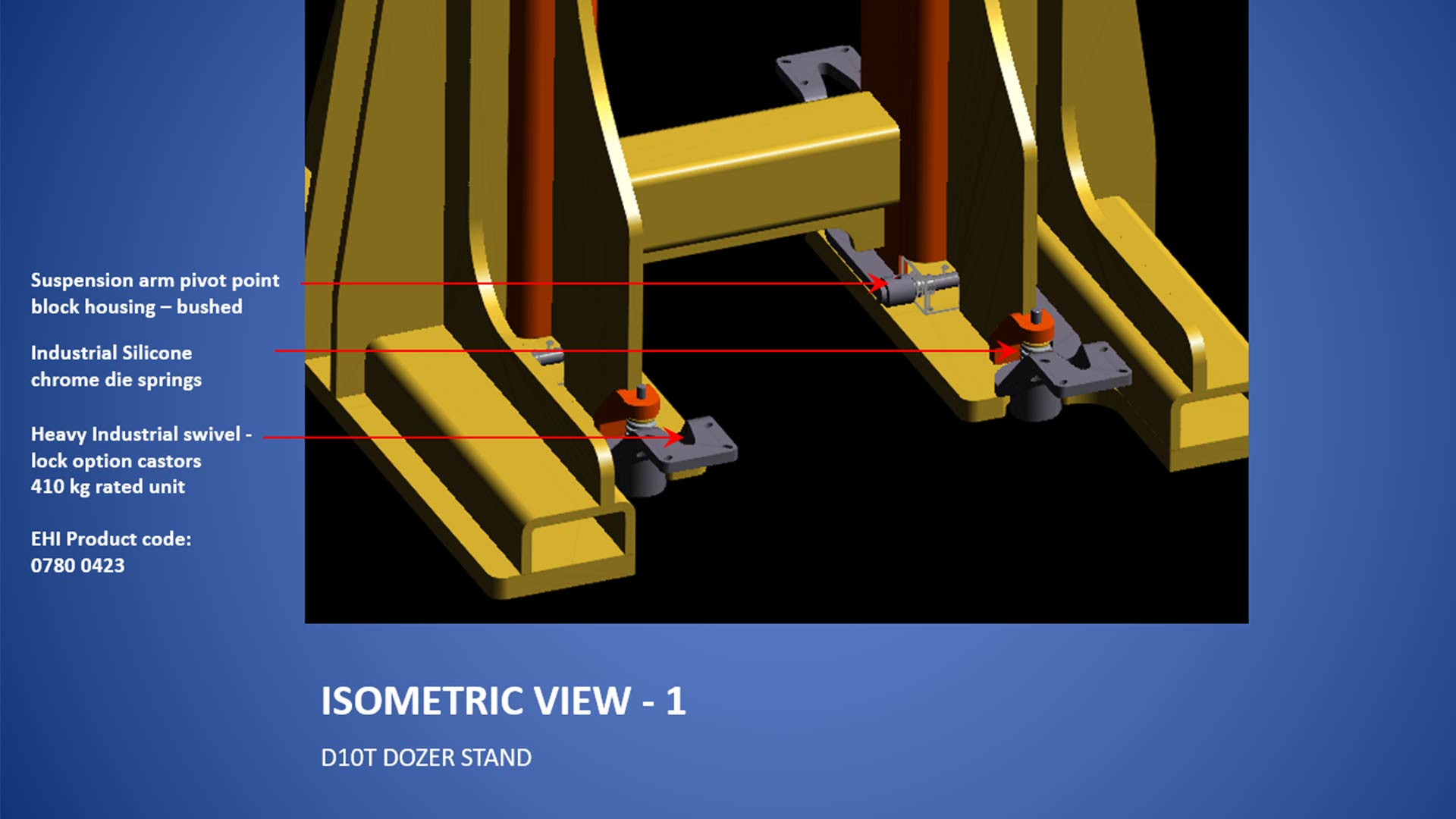

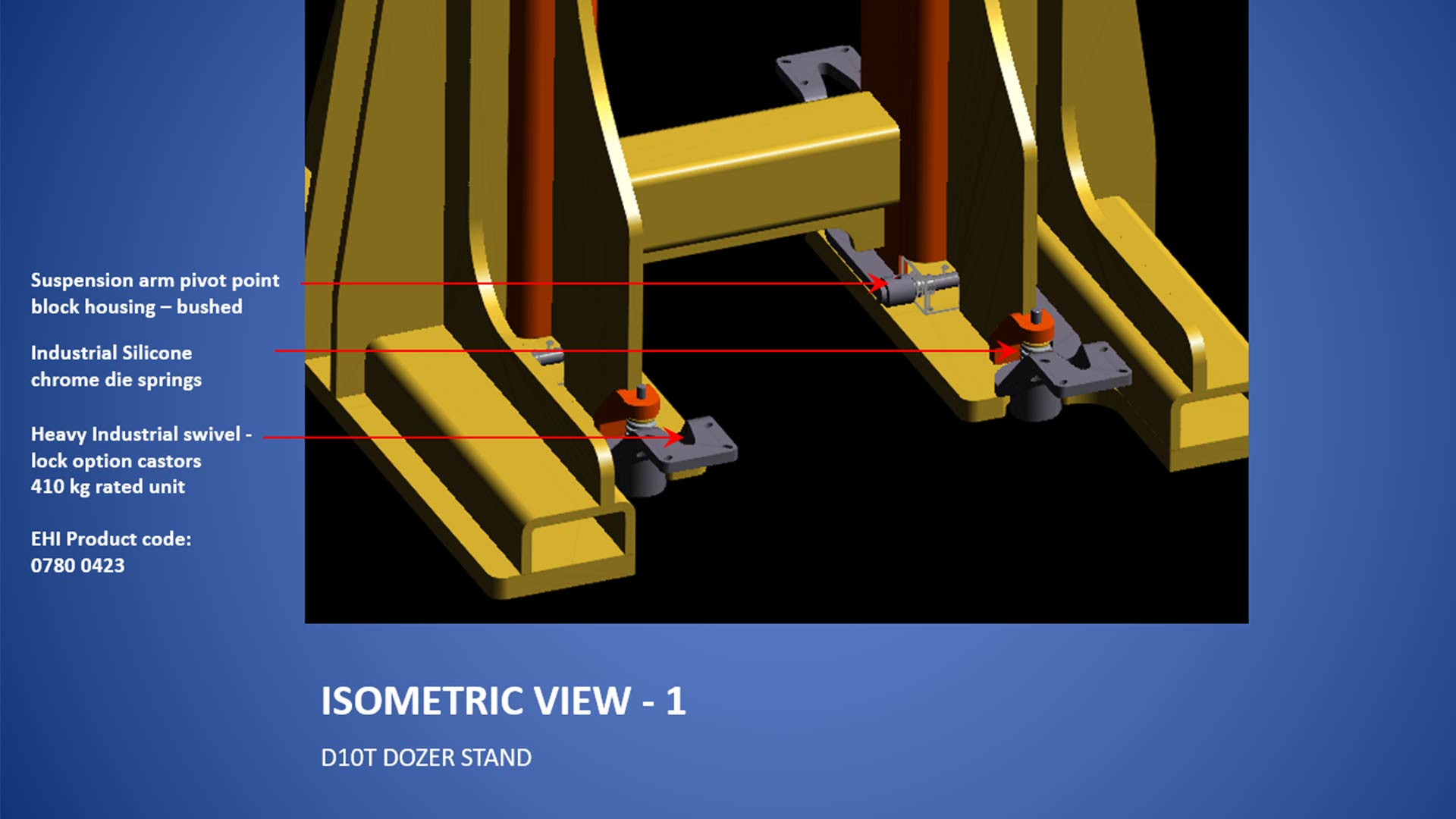

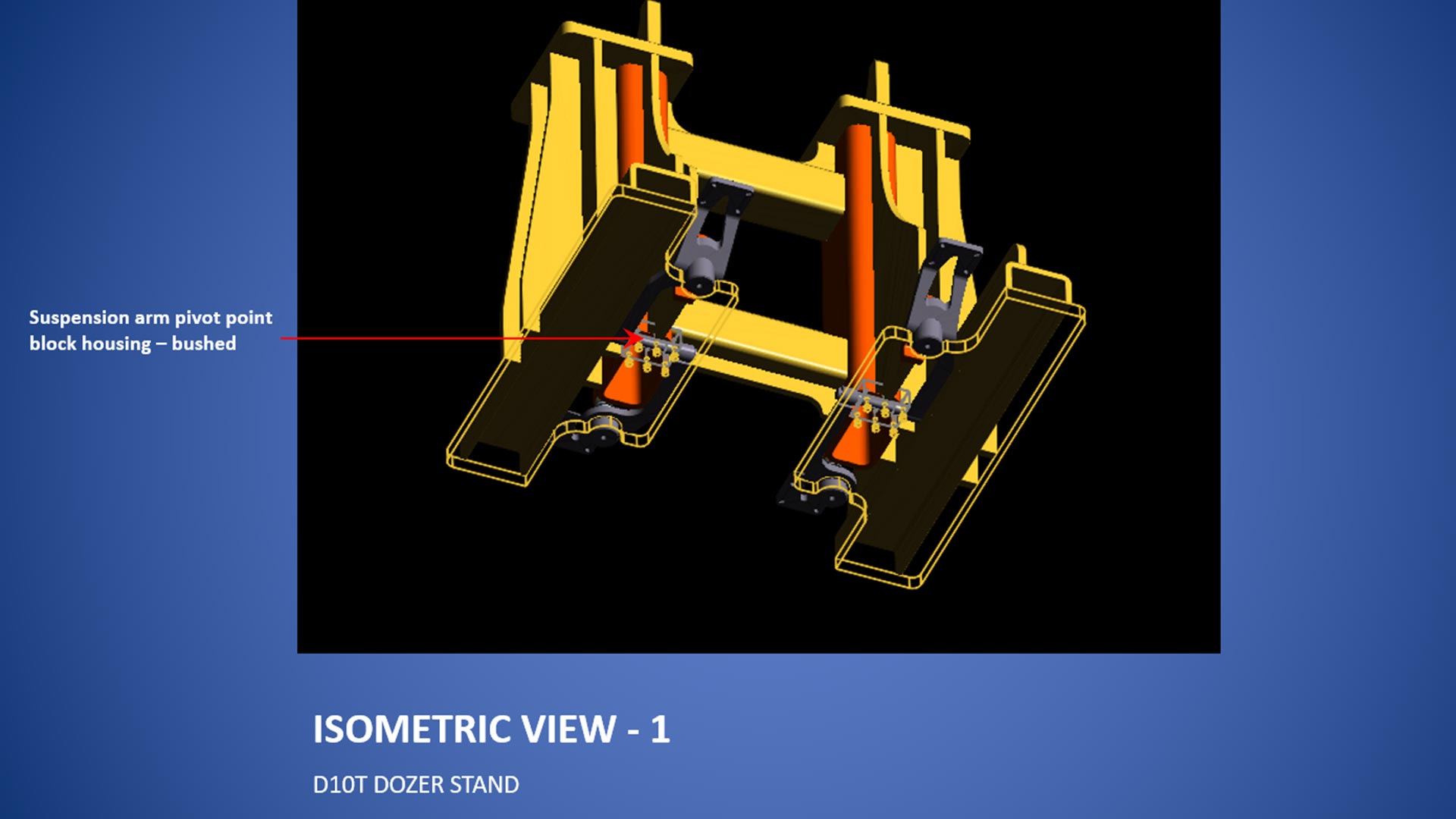

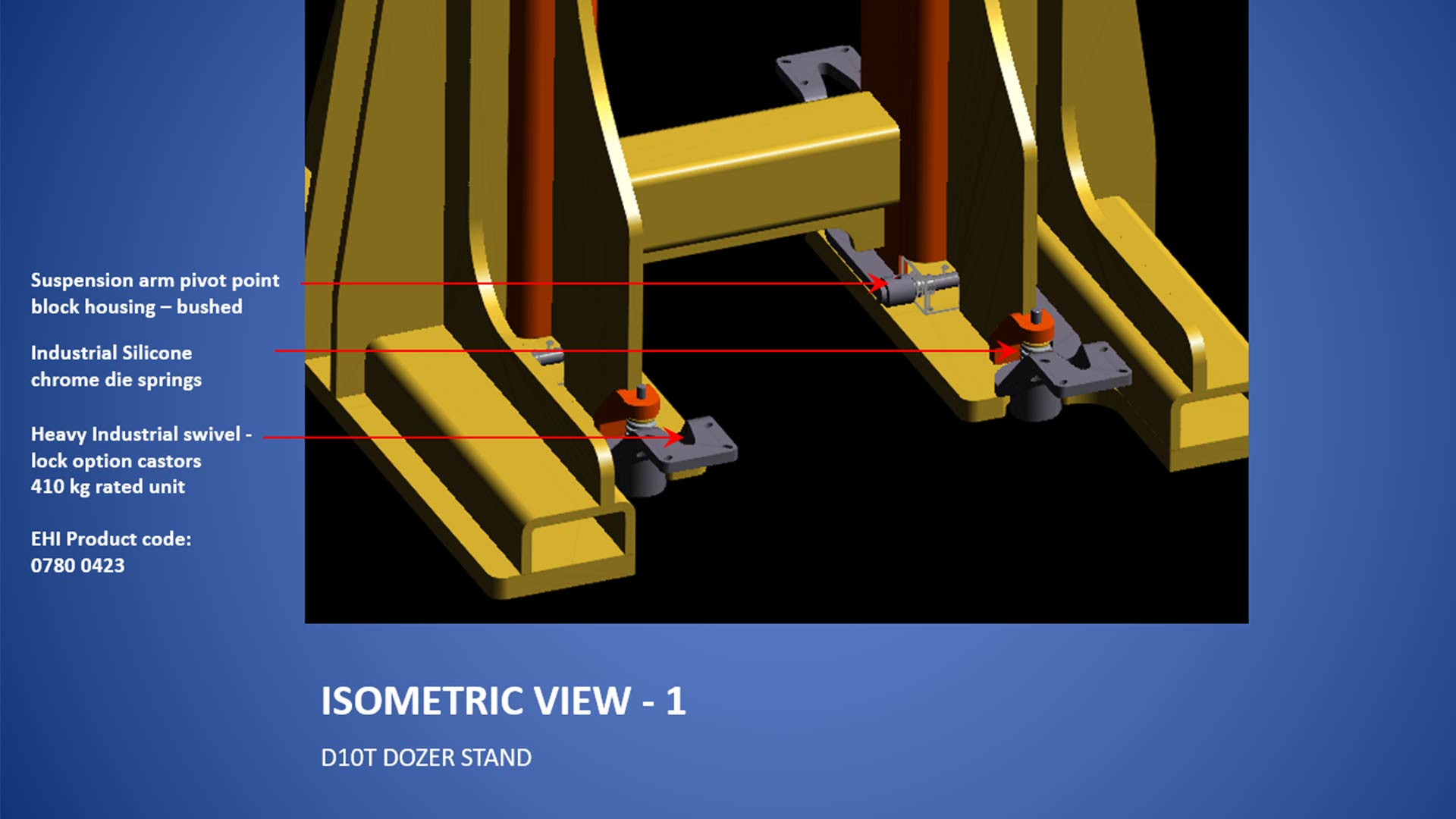

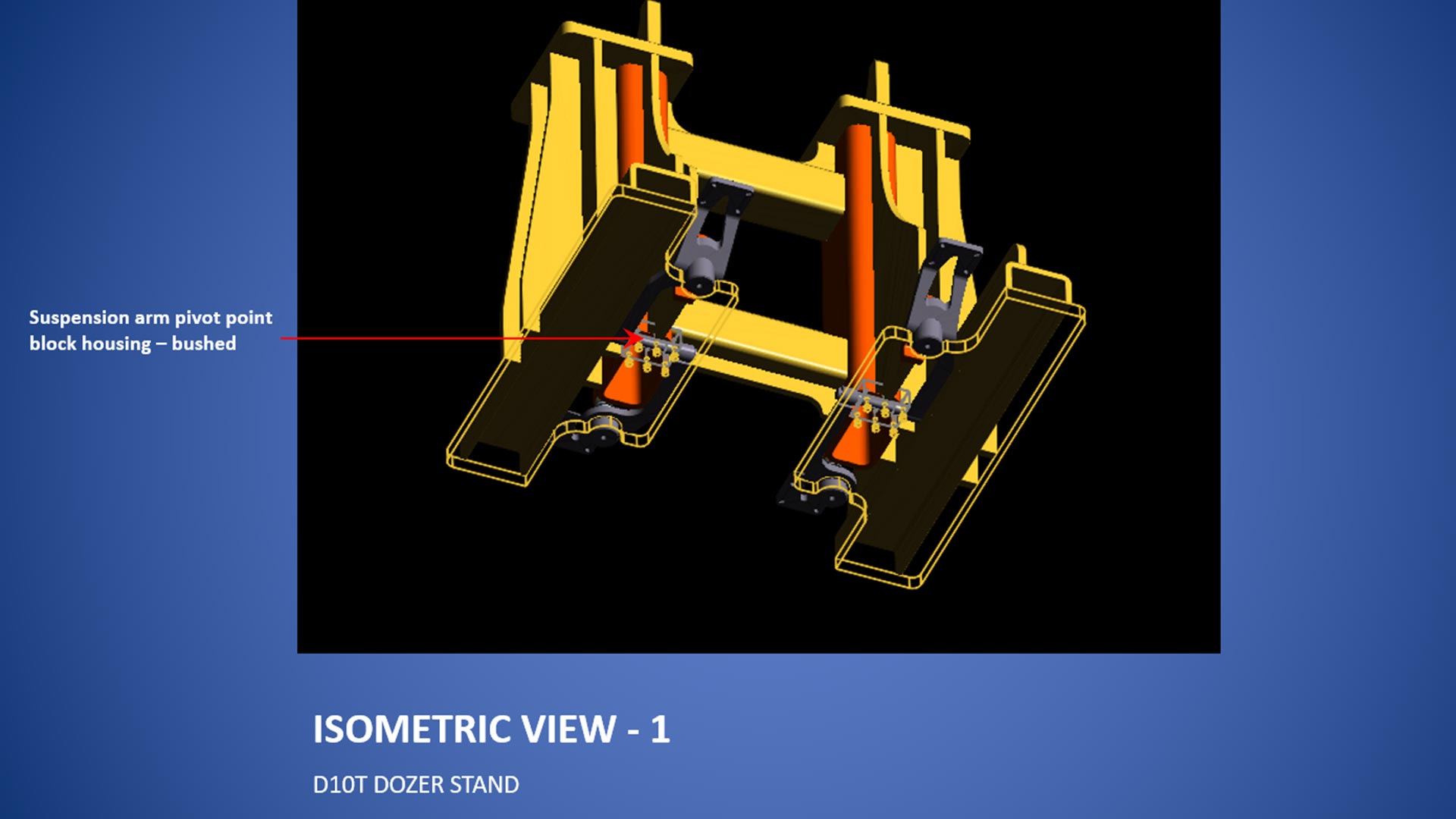

This incident almost caused a loss of life which called for an overhaul in the aspects of safety relating to the use of dozer stands. A new design was modeled and fabricated with new features such as:

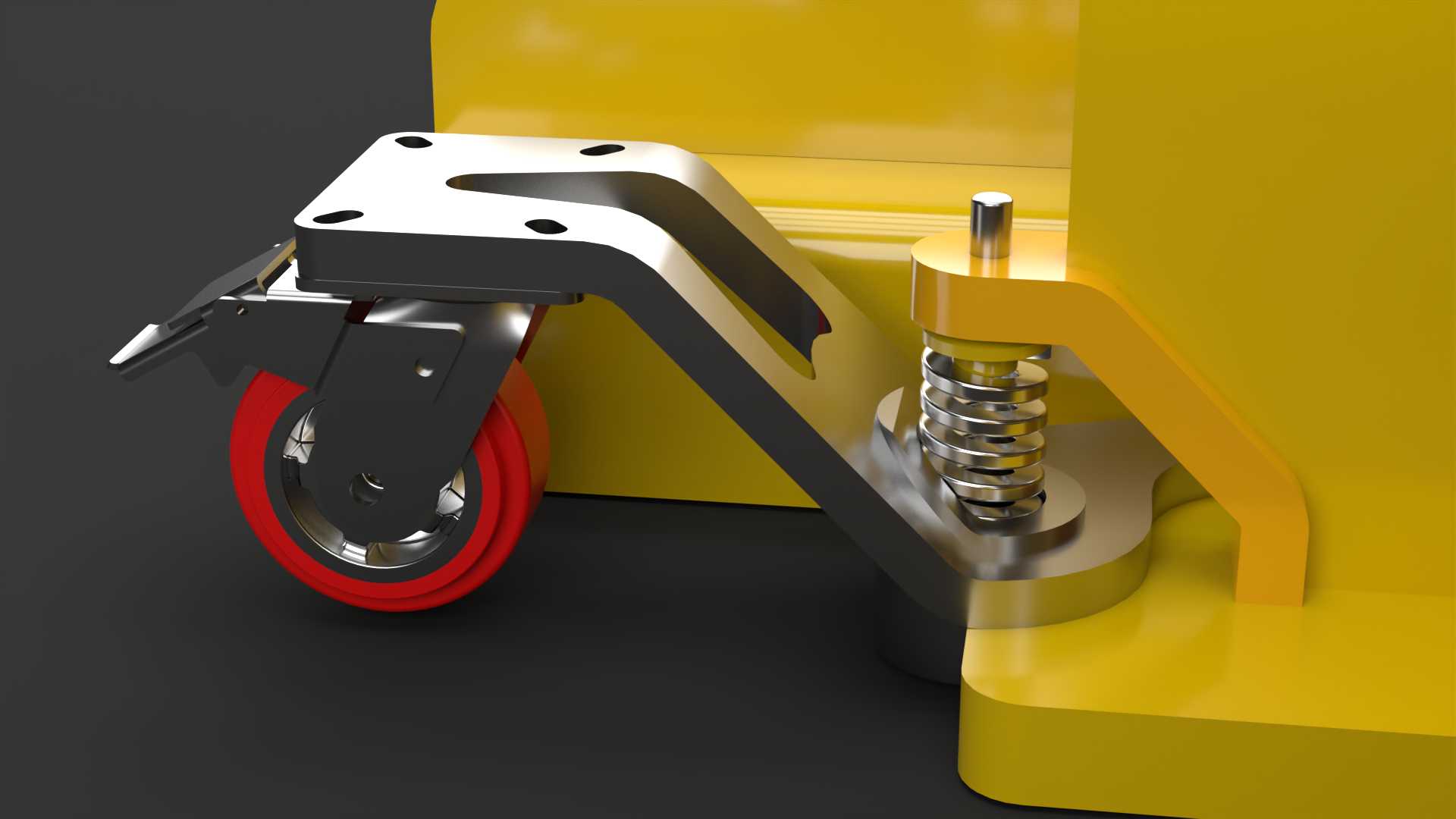

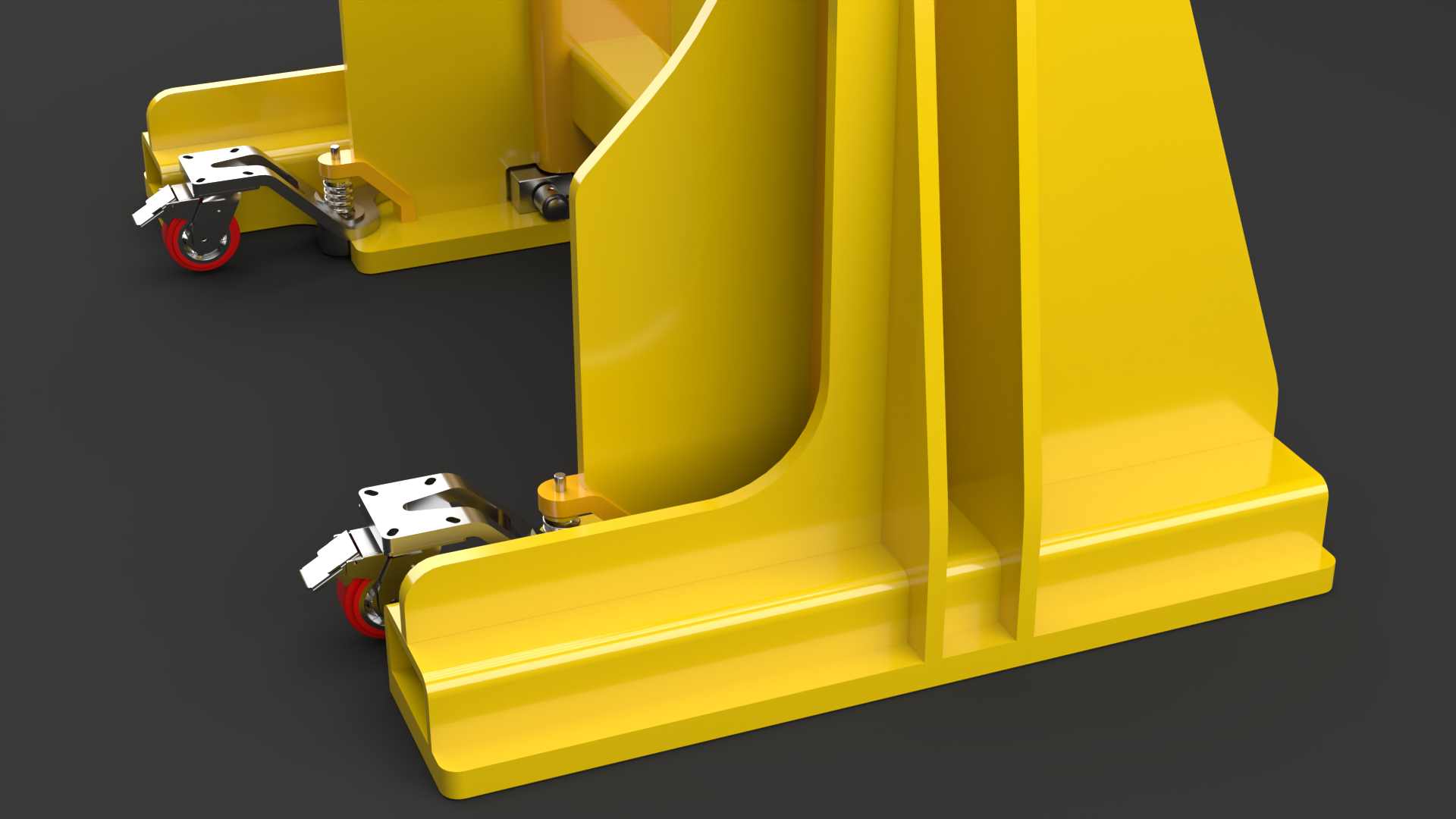

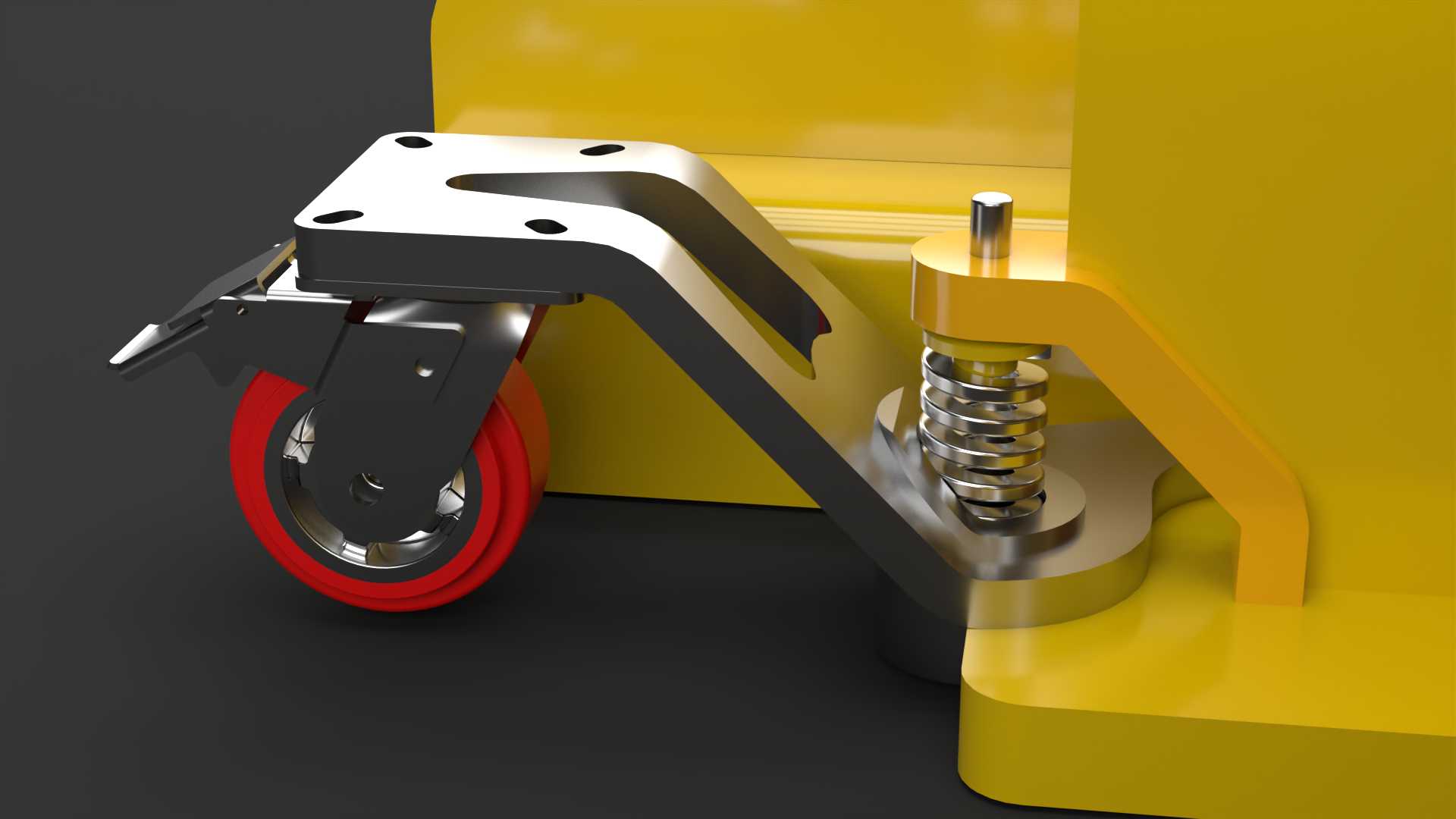

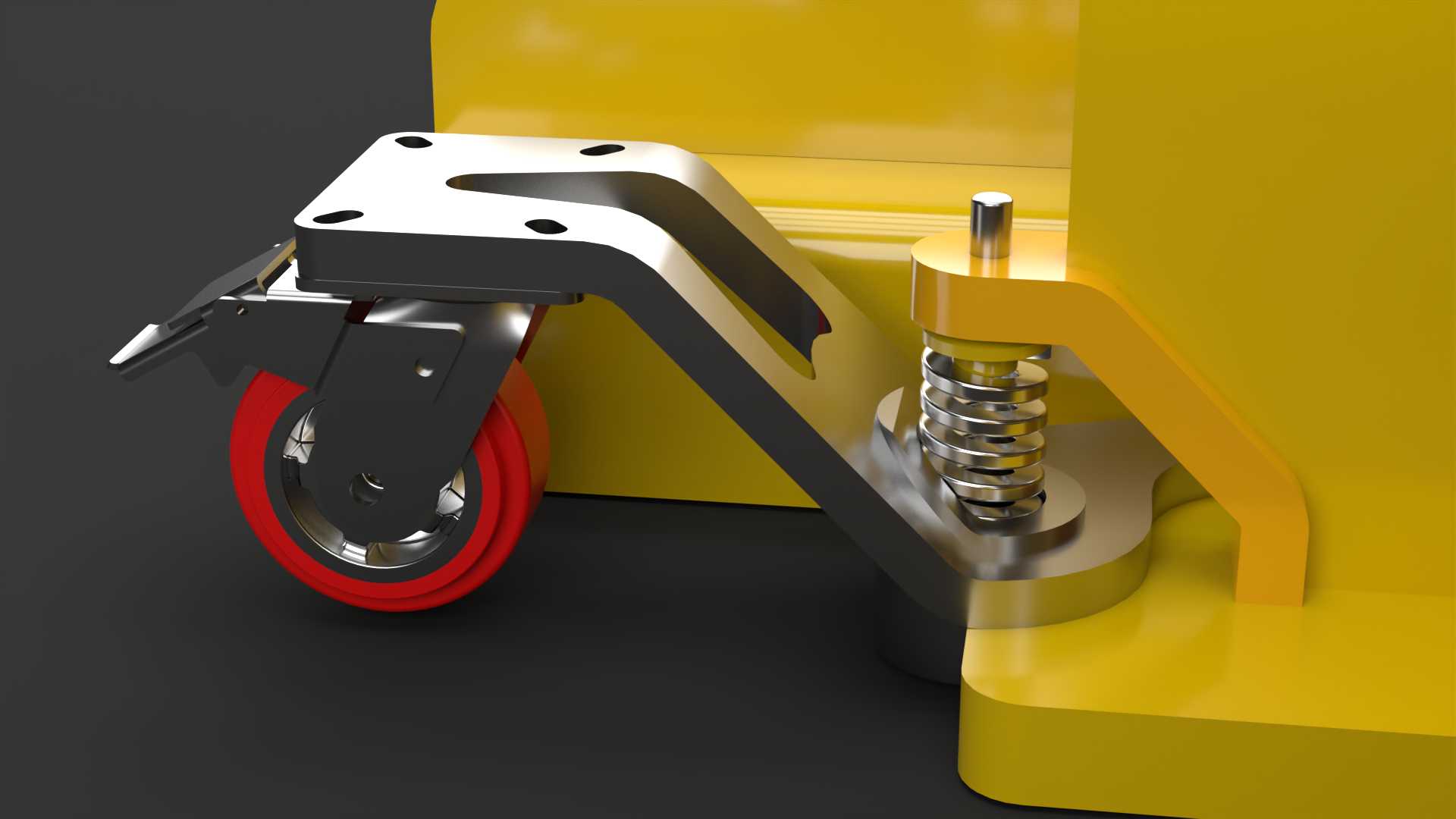

A suspension arm pivot point block housing – bushed

Industrial Silicone chrome die springs

Heavy Industrial swivel - lock option castors 410 kg rated unit

M16 ball drive adjustment screw – sets load suspension point

Scope of Work

This incident almost caused a loss of life which called for an overhaul in the aspects of safety relating to the use of dozer stands. A new design was modeled and fabricated with new features such as:

A suspension arm pivot point block housing – bushed

Industrial Silicone chrome die springs

Heavy Industrial swivel - lock option castors 410 kg rated unit

M16 ball drive adjustment screw – sets load suspension point

Scope of Work

This incident almost caused a loss of life which called for an overhaul in the aspects of safety relating to the use of dozer stands. A new design was modeled and fabricated with new features such as:

A suspension arm pivot point block housing – bushed

Industrial Silicone chrome die springs

Heavy Industrial swivel - lock option castors 410 kg rated unit

M16 ball drive adjustment screw – sets load suspension point

Objectives

Remove the high risk potential when working with dozer stands.

Objectives

Remove the high risk potential when working with dozer stands.

Objectives

Remove the high risk potential when working with dozer stands.

Innovative Thinking

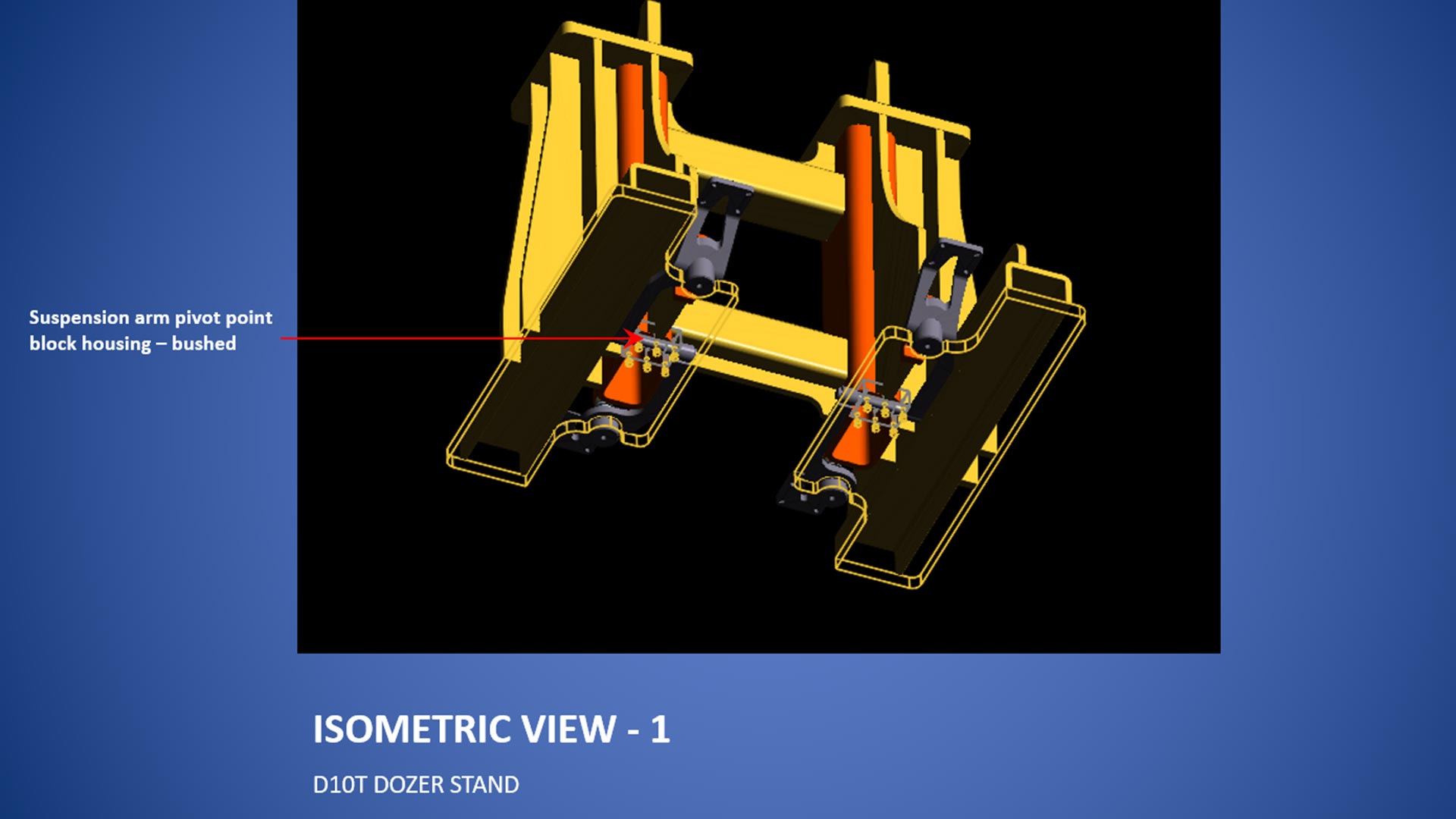

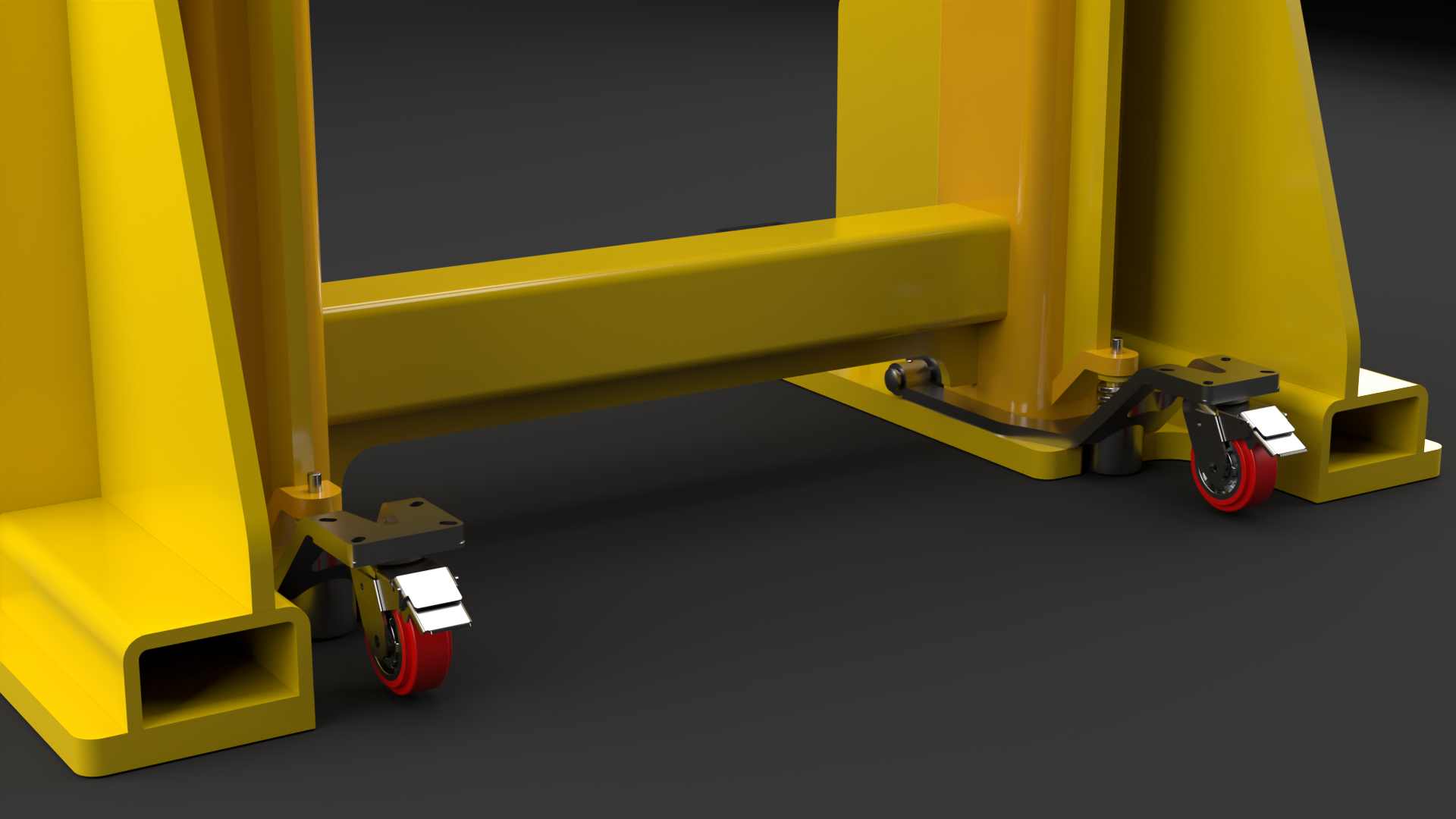

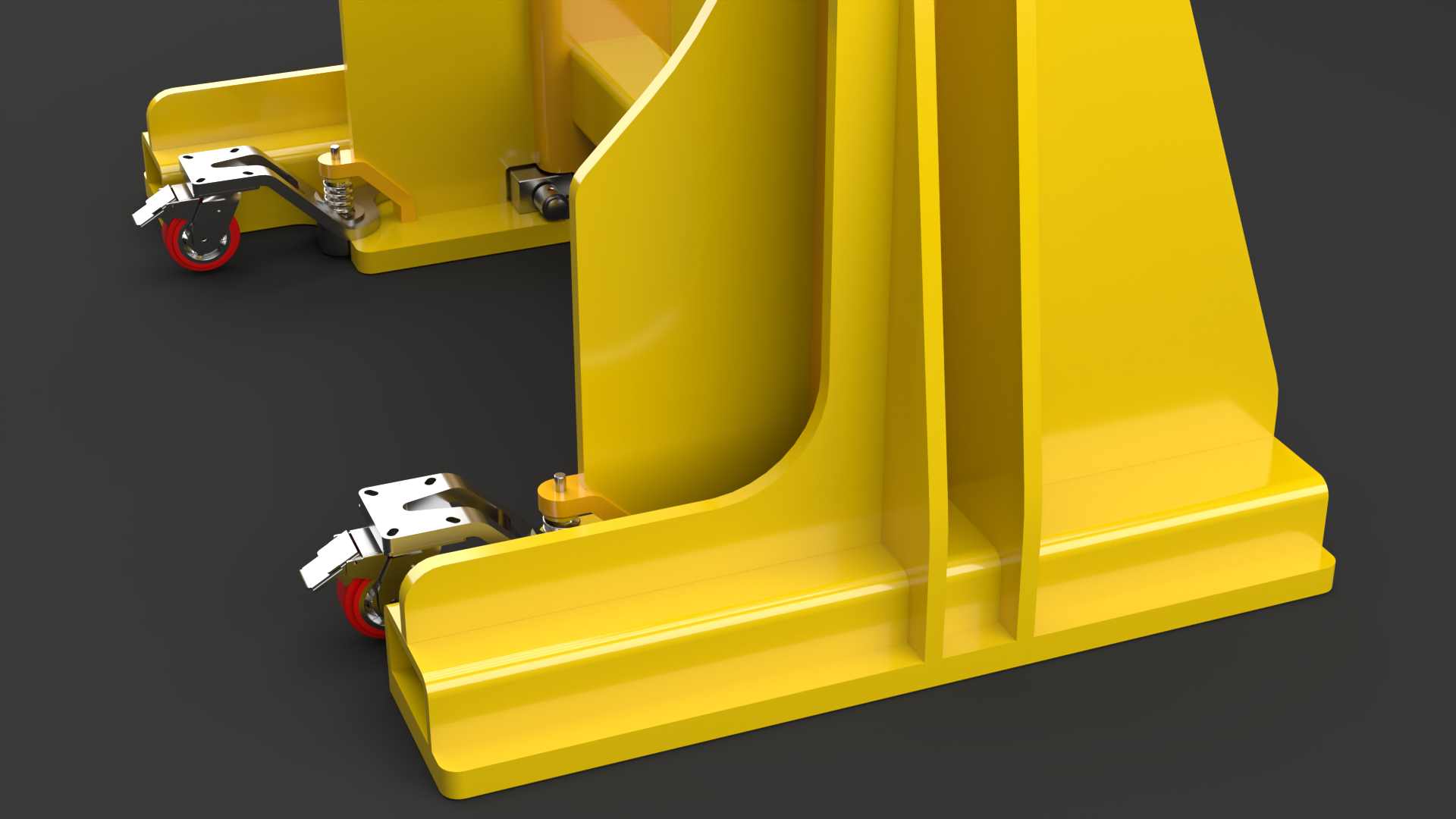

The new design was later amended to accommodate the stands being rolled into position with the aid of spring suspended swivel lock wheels. Once a load weight is detected the slide function gets deactivated based on weight.

The setup process is expedited without the need for multiple CAT jacks.

This process removes the risk of a dozer fall throughout these high risk maintenance operations.

Innovative Thinking

The new design was later amended to accommodate the stands being rolled into position with the aid of spring suspended swivel lock wheels. Once a load weight is detected the slide function gets deactivated based on weight.

The setup process is expedited without the need for multiple CAT jacks.

This process removes the risk of a dozer fall throughout these high risk maintenance operations.

Innovative Thinking

The new design was later amended to accommodate the stands being rolled into position with the aid of spring suspended swivel lock wheels. Once a load weight is detected the slide function gets deactivated based on weight.

The setup process is expedited without the need for multiple CAT jacks.

This process removes the risk of a dozer fall throughout these high risk maintenance operations.

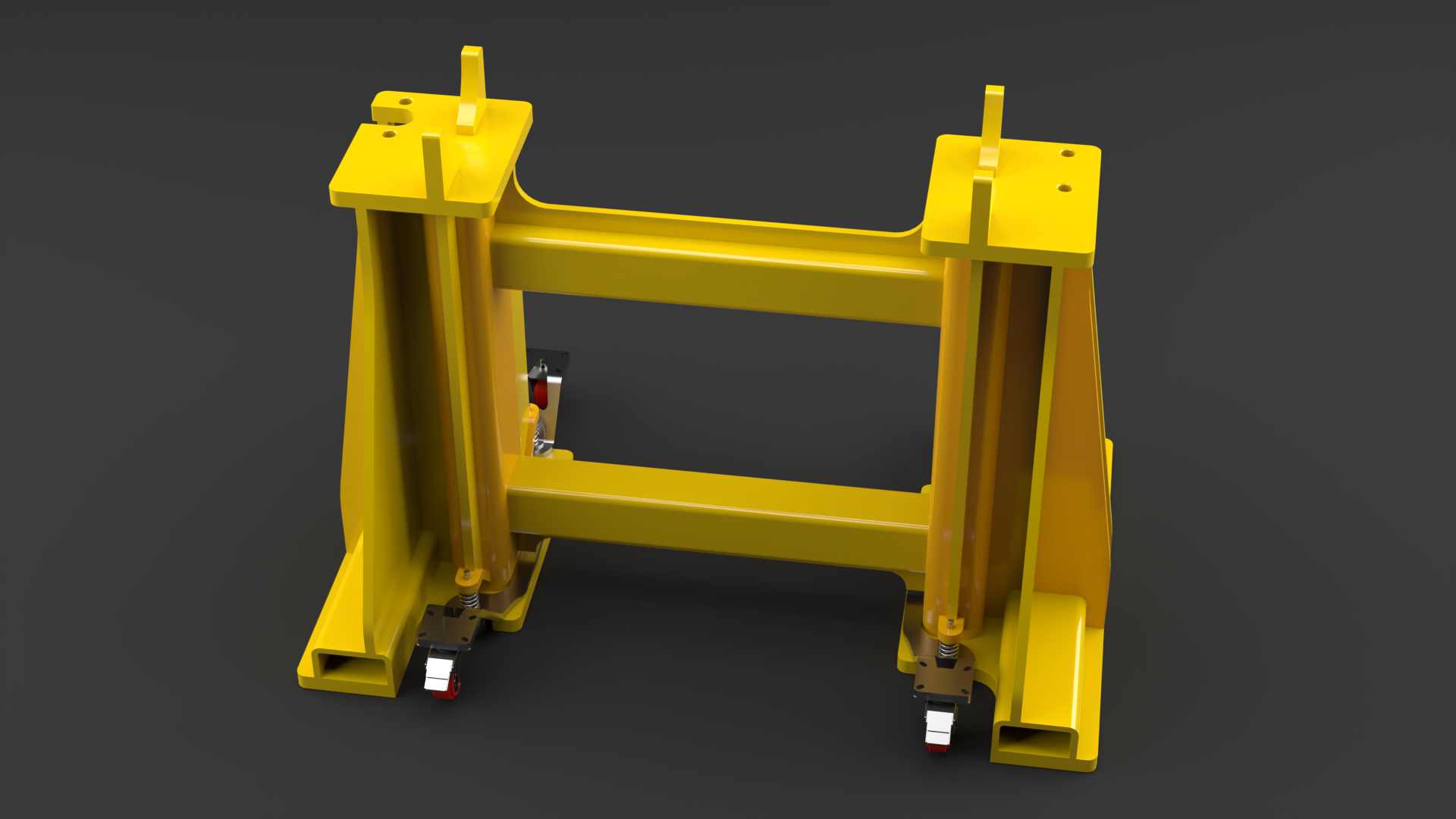

Accomplishments

Two dozer stands of different sizes were modeled and fabricated. It then became an industry standard across Rio Tinto’s Iron Ore mine sites.

Accomplishments

Two dozer stands of different sizes were modeled and fabricated. It then became an industry standard across Rio Tinto’s Iron Ore mine sites.

Accomplishments

Two dozer stands of different sizes were modeled and fabricated. It then became an industry standard across Rio Tinto’s Iron Ore mine sites.

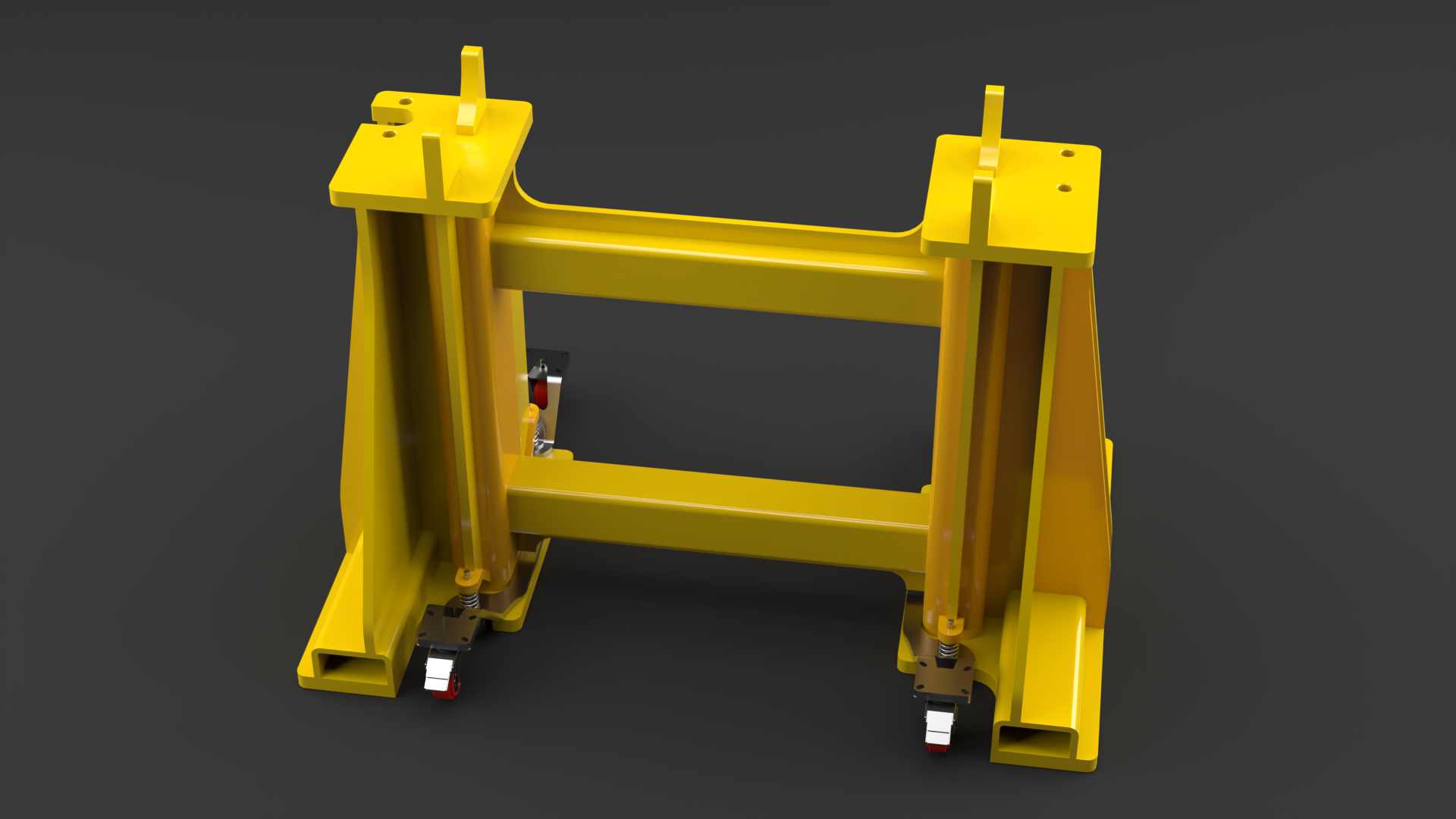

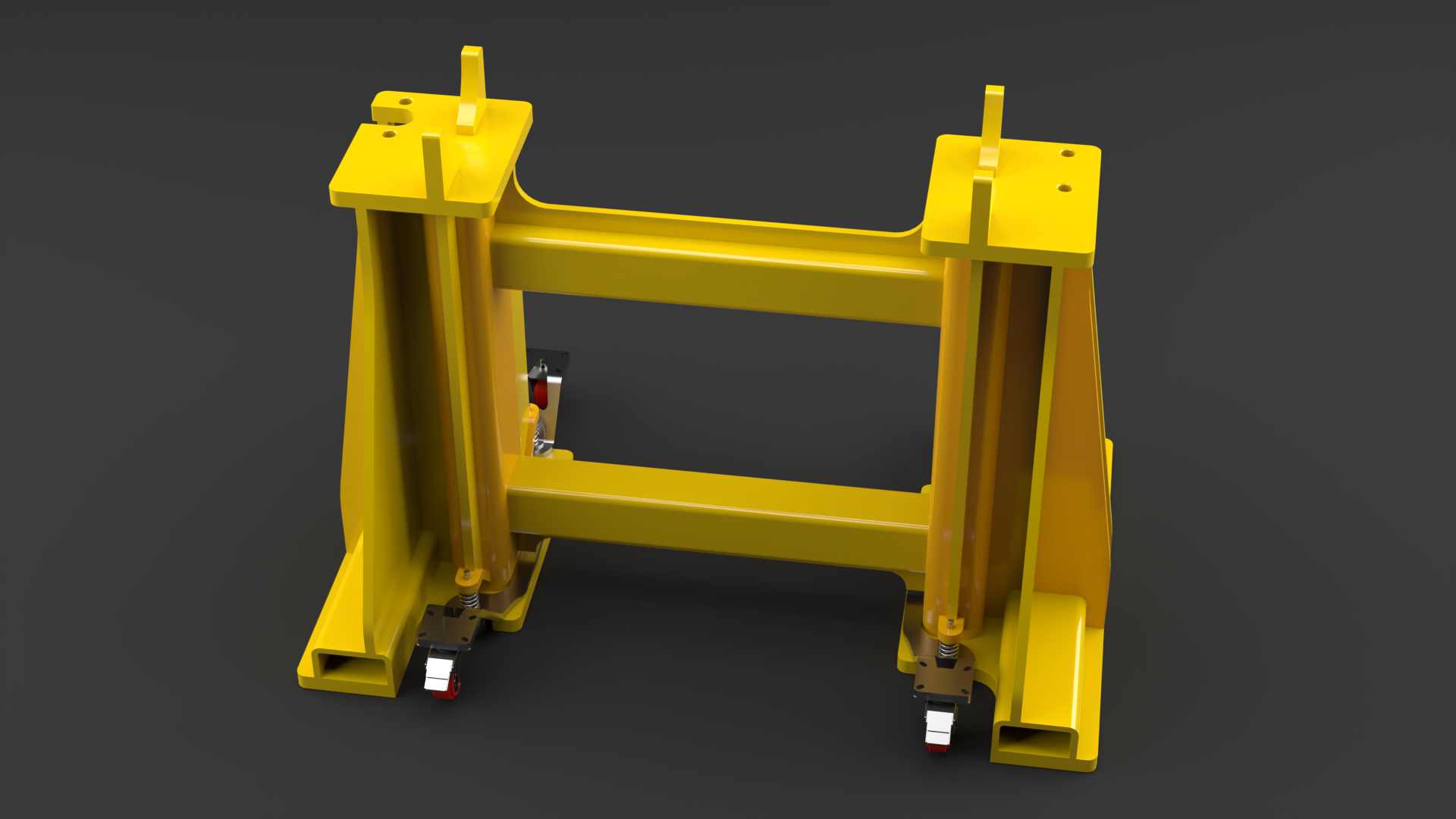

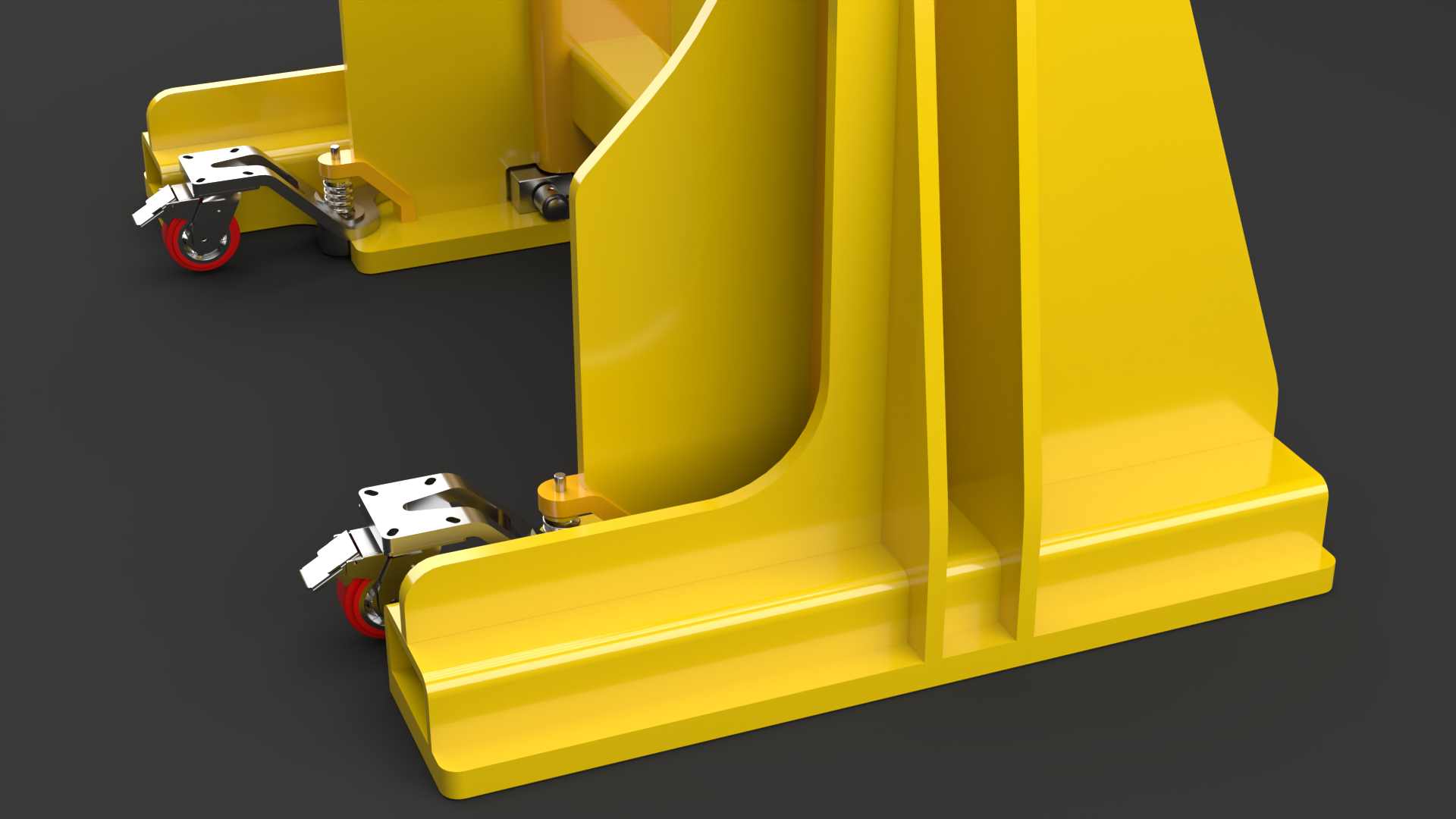

Dozer Stand - view 1

View 2

Dozer Stand - view 1

View 2

Dozer Stand - view 1

View 2

D11R T Dozer Stand Overview

D11R T Dozer Stand Overview

D11R T Dozer Stand Overview

Chrome die springs

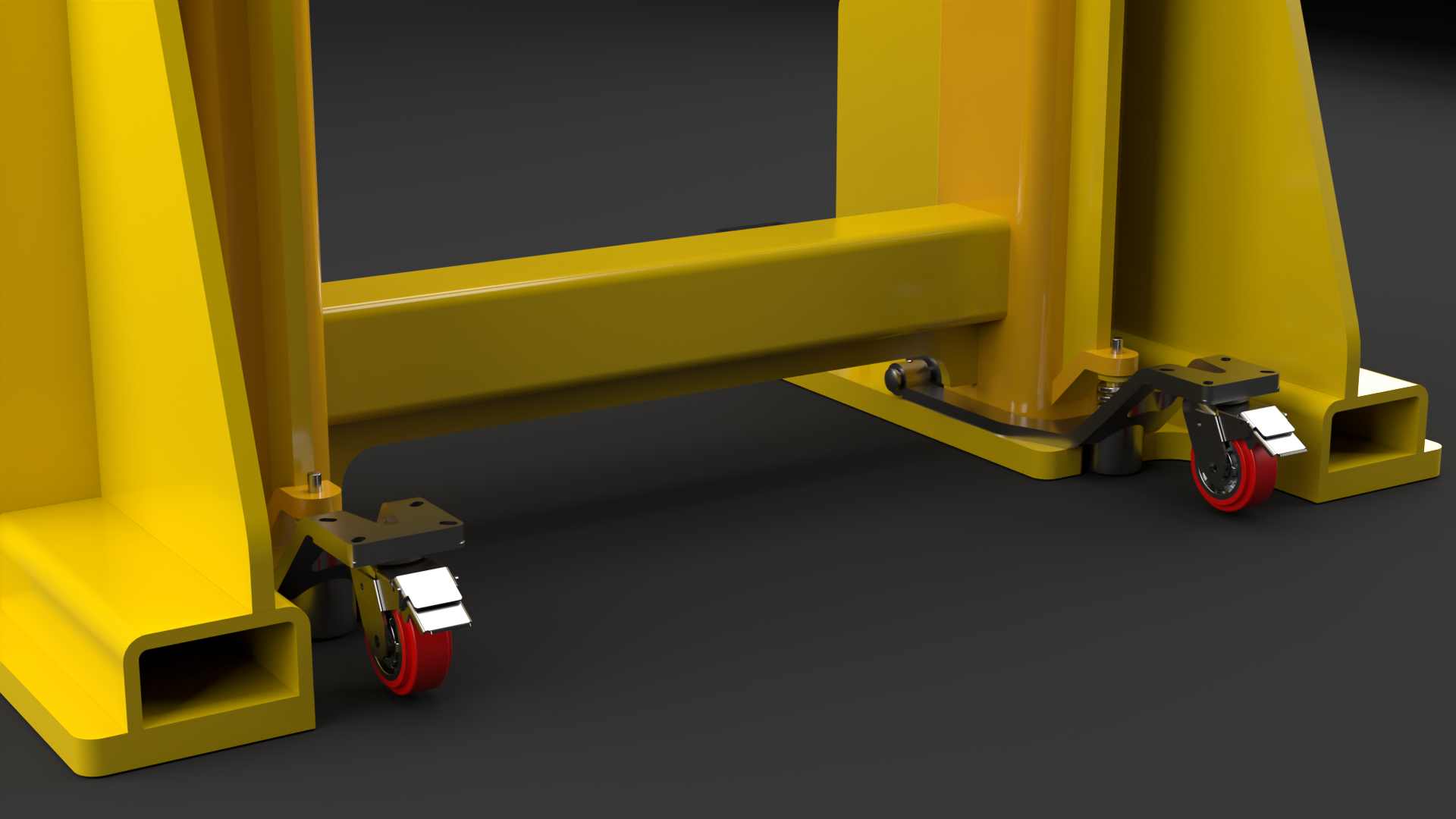

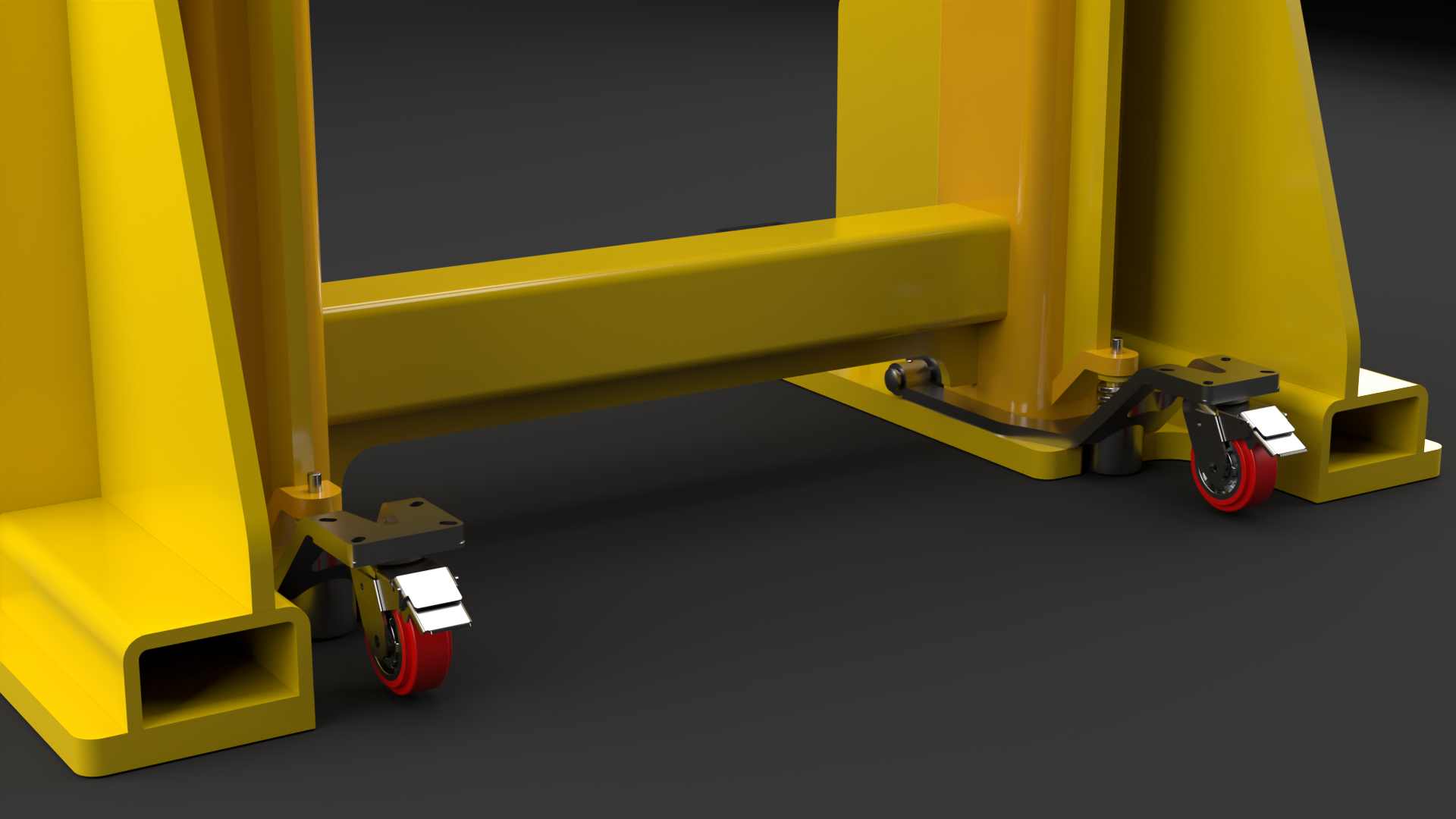

Castor wheels isometric view

Castor wheels alternate view

Chrome die springs

Castor wheels isometric view

Castor wheels alternate view

Chrome die springs

Castor wheels isometric view