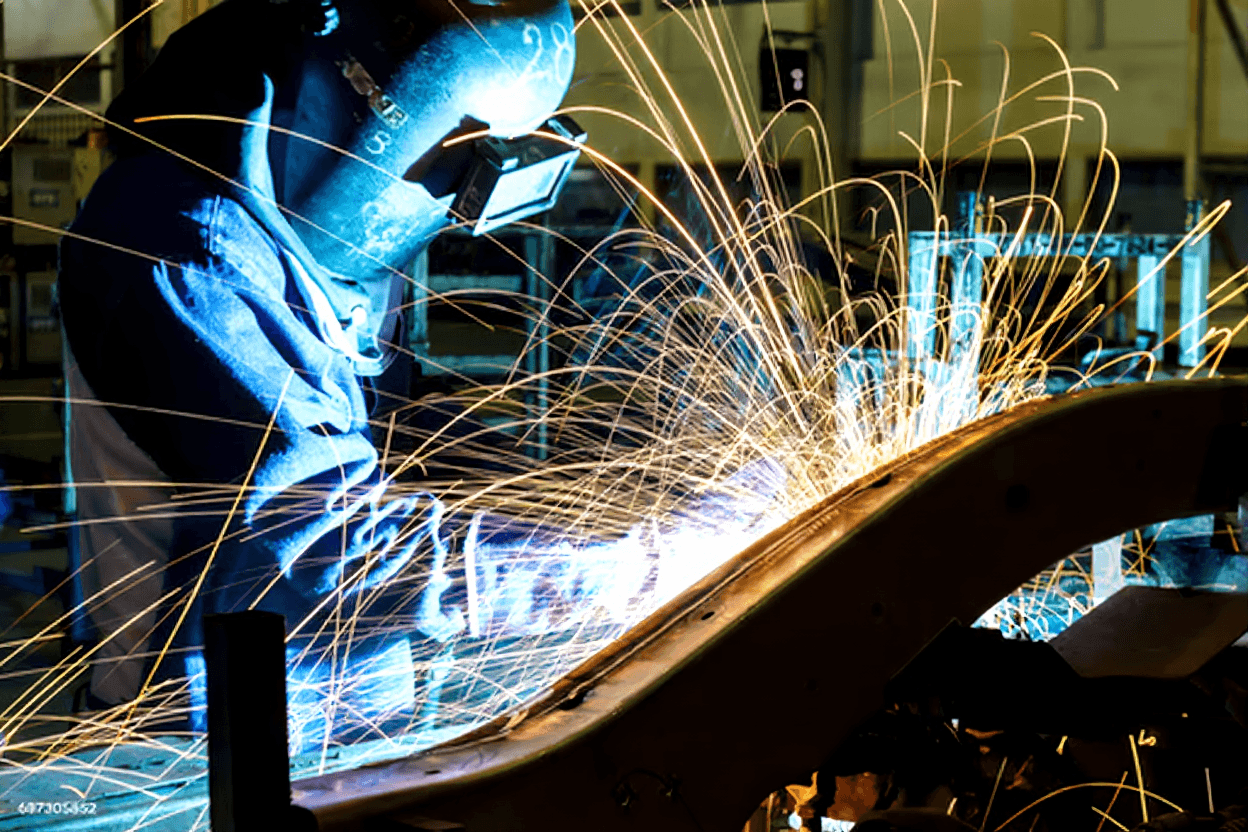

Fabrication & Installs

Fabrication & Installs

Fabrication & Installs

Turnkey Project Execution

Assets have complex, integrated lifecycles. We have significant experience in generating a high standard of deliverables for both fabrication and mechanical projects.

With over 30 years of custom numerical manufacturing and fabrication expertise, IMS will deliver the most cost-effective solution.

Turnkey Project Execution

Assets have complex, integrated lifecycles. We have significant experience in generating a high standard of deliverables for both fabrication and mechanical projects.

With over 30 years of custom numerical manufacturing and fabrication expertise, IMS will deliver the most cost-effective solution.

Turnkey Project Execution

Assets have complex, integrated lifecycles. We have significant experience in generating a high standard of deliverables for both fabrication and mechanical projects.

With over 30 years of custom numerical manufacturing and fabrication expertise, IMS will deliver the most cost-effective solution.

Project Management Includes:

Technical engineering support and proposed processing practices

Reliability Optimisation and maintenance strategy studies

Shutdown asset scoping and commissioning methodologies

Wear liner management and optimisation maintenance strategies

Wear liner management inspections and 3D laser wear monitoring shutdown reporting

End to end turnkey project management execution

Project Management Includes:

Technical engineering support and proposed processing practices

Reliability Optimisation and maintenance strategy studies

Shutdown asset scoping and commissioning methodologies

Wear liner management and optimisation maintenance strategies

Wear liner management inspections and 3D laser wear monitoring shutdown reporting

End to end turnkey project management execution

Project Management Includes:

Technical engineering support and proposed processing practices

Reliability Optimisation and maintenance strategy studies

Shutdown asset scoping and commissioning methodologies

Wear liner management and optimisation maintenance strategies

Wear liner management inspections and 3D laser wear monitoring shutdown reporting

End to end turnkey project management execution

Secondment Support On-site Engineering

IMS caters for AD HOC site mechanical engineering and or reliability engineering contract support within critical engineering disciplinaries. We provide temporary short- and long-term secondment resources for both fixed plant and surface mining assets:

Project Engineering - Lead Execution

Mechanical Engineering support

Mechanical Engineering maintenance support

Secondment Support On-site Engineering

IMS caters for AD HOC site mechanical engineering and or reliability engineering contract support within critical engineering disciplinaries. We provide temporary short- and long-term secondment resources for both fixed plant and surface mining assets:

Project Engineering - Lead Execution

Mechanical Engineering support

Mechanical Engineering maintenance support

Secondment Support On-site Engineering

IMS caters for AD HOC site mechanical engineering and or reliability engineering contract support within critical engineering disciplinaries. We provide temporary short- and long-term secondment resources for both fixed plant and surface mining assets:

Project Engineering - Lead Execution

Mechanical Engineering support

Mechanical Engineering maintenance support

Asset Reliability Engineering Solutions:

HME and or Fixed Plant Assets

Reliability Centered Maintenance (RCM)

Root cause analysis (RCA)

Fail mode effect analysis (FMEA)

Fault tree analysis (FTA)

Criticality analysis CA identification

Change management initiations (CM)

Safe work instructions modifications and development (SWI)

OEM project liaising interactions and support networking

Reliability Engineering (RE) asset reporting/actioning

Asset Reliability Engineering Solutions:

HME and or Fixed Plant Assets

Reliability Centered Maintenance (RCM)

Root cause analysis (RCA)

Fail mode effect analysis (FMEA)

Fault tree analysis (FTA)

Criticality analysis CA identification

Change management initiations (CM)

Safe work instructions modifications and development (SWI)

OEM project liaising interactions and support networking

Reliability Engineering (RE) asset reporting/actioning

Asset Reliability Engineering Solutions:

HME and or Fixed Plant Assets

Reliability Centered Maintenance (RCM)

Root cause analysis (RCA)

Fail mode effect analysis (FMEA)

Fault tree analysis (FTA)

Criticality analysis CA identification

Change management initiations (CM)

Safe work instructions modifications and development (SWI)

OEM project liaising interactions and support networking

Reliability Engineering (RE) asset reporting/actioning