Primary Sizer Oil Cooler Extension

Scope of Work

Two new Hydac oil coolers required installation to the sizer gearboxes after a breakdown. The gearboxes were adjacent to the coolers which caused a high amount of vibration and often resulted in essential maintenance to the Hydac oil coolers.

Objectives

- Redesign the piping lines that connect from the gearboxes to the coolers.

- Rework placement of the system inlet (ball valve).

- System outlet (check valve) for the new Hydac cooling systems.

Challenges Involved

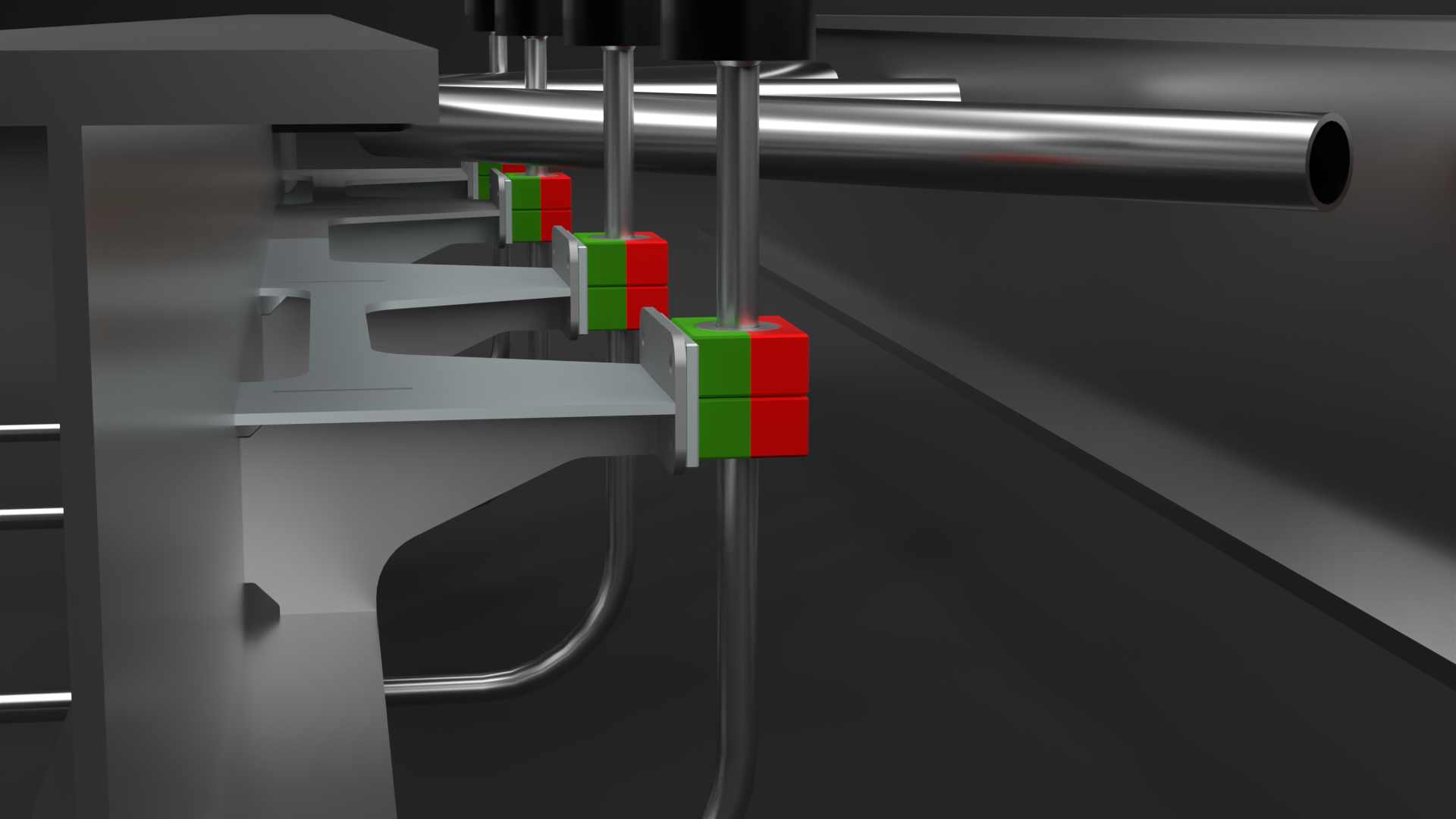

The high vibration levels in the area reduced durability of the Hydac cooler. Position of the inlet and outlet on the coolers were different and required configuration. Four stainless steel piping lines required custom designs with stop valves at the ends.

(New Hydac oil cooler)

(Green gearbox + old cooler view 1)

(View 2)

Innovative Thinking

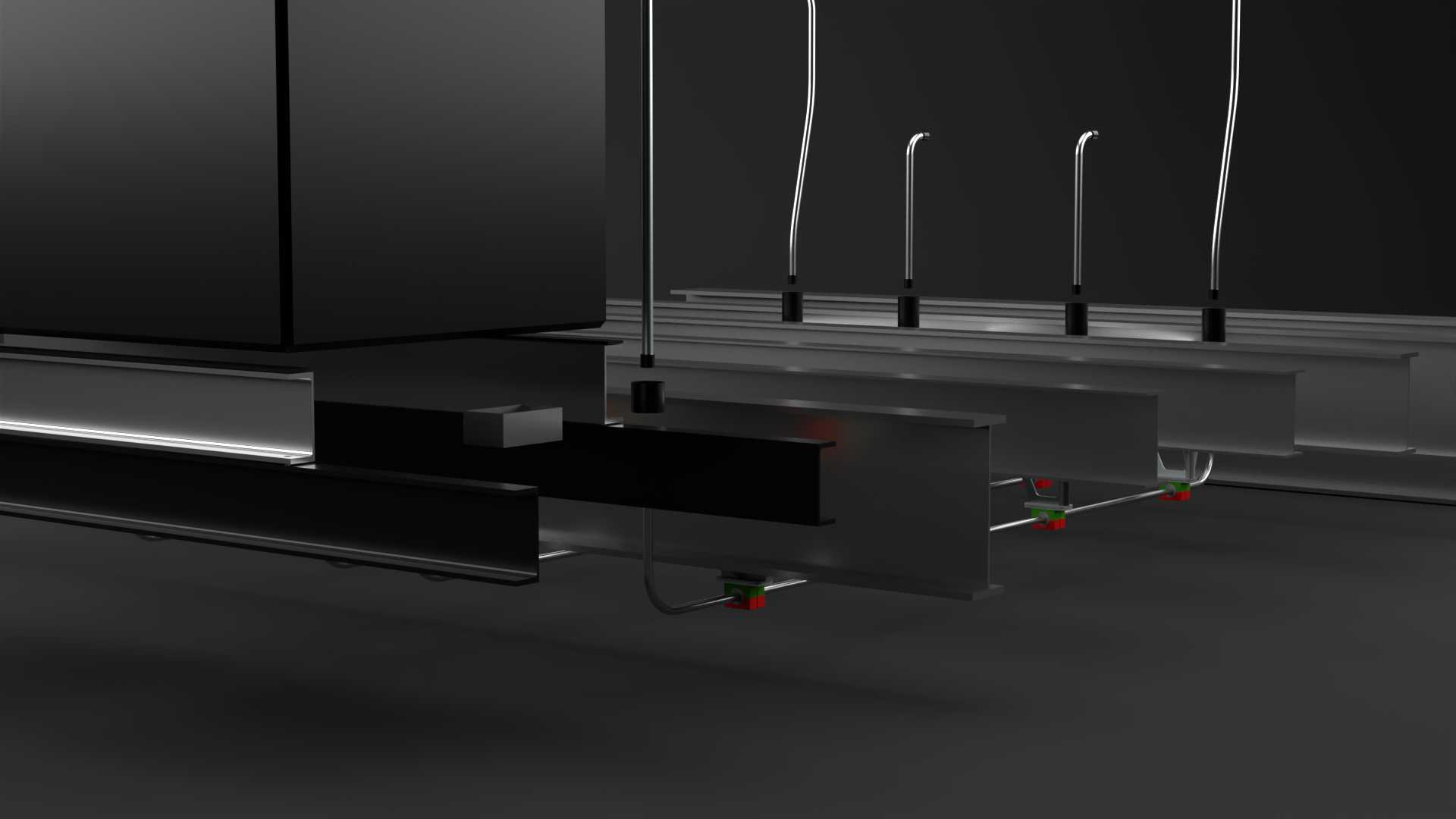

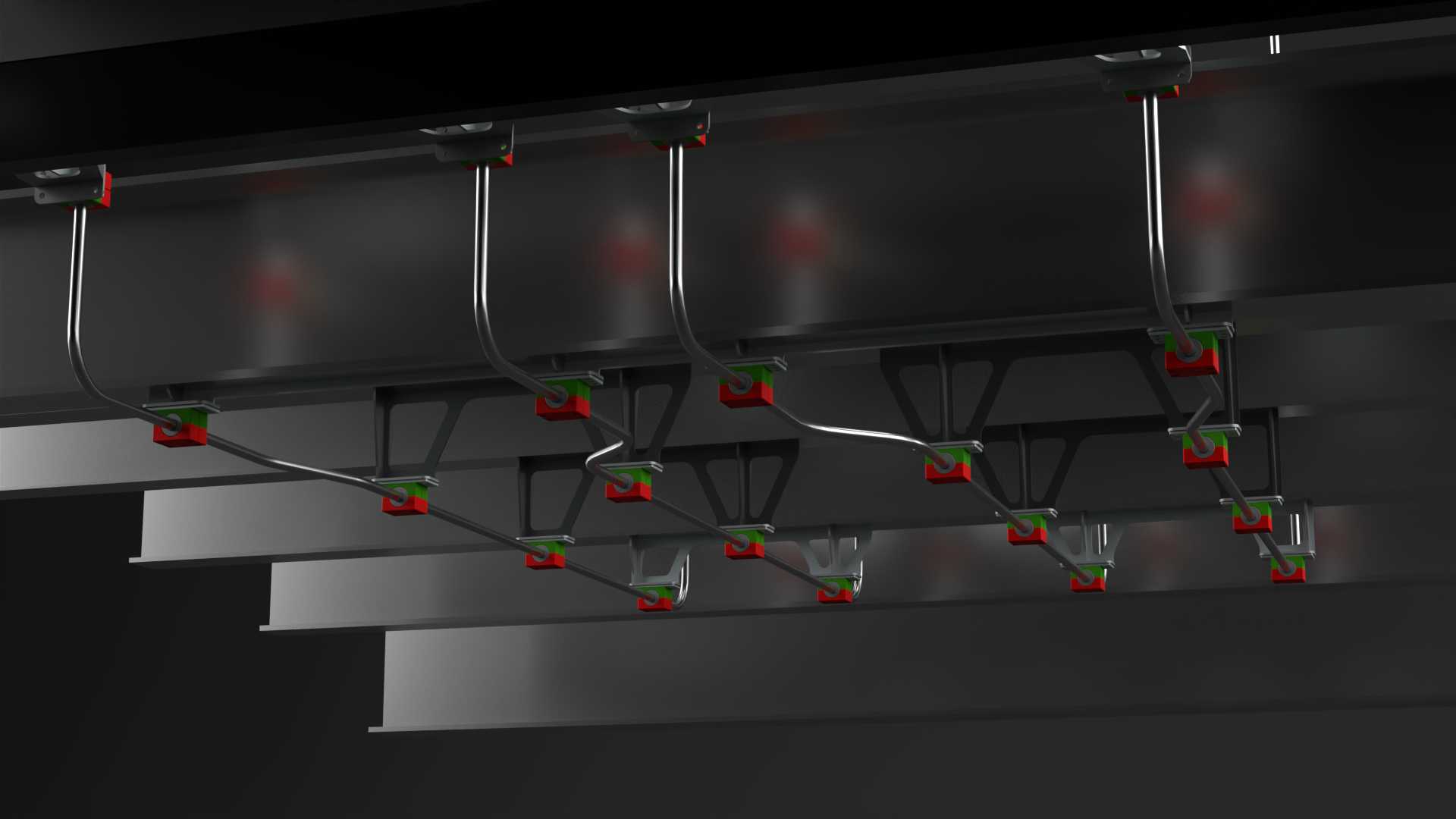

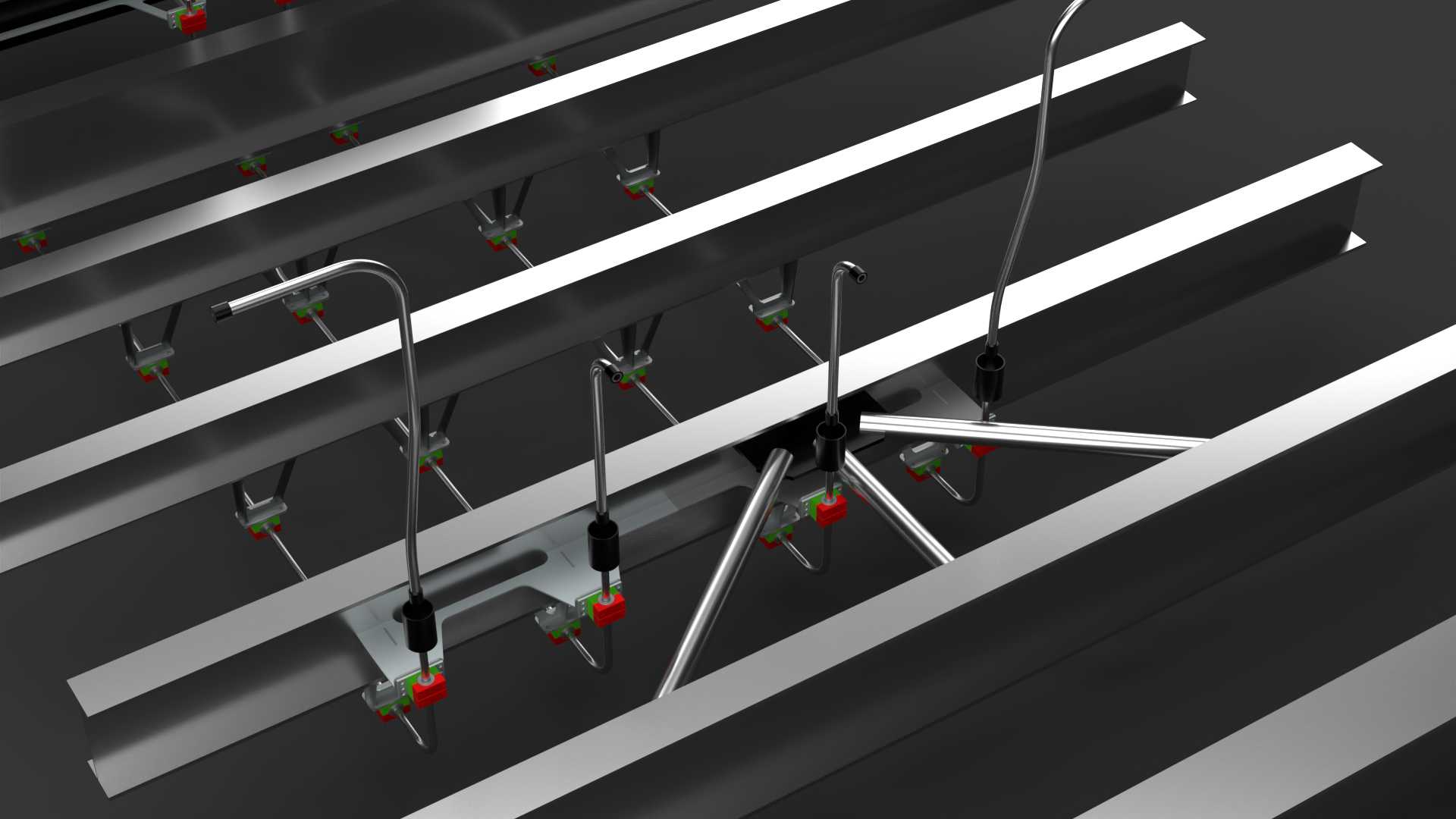

Creating distance and height between the cooler and the gearbox would significantly reduce vibration. To keep the 16 meters of piping out of harm's way, it was attached underneath the platform's support beams with Stauff rubber profile mount clamps to further reduce the vibration levels.

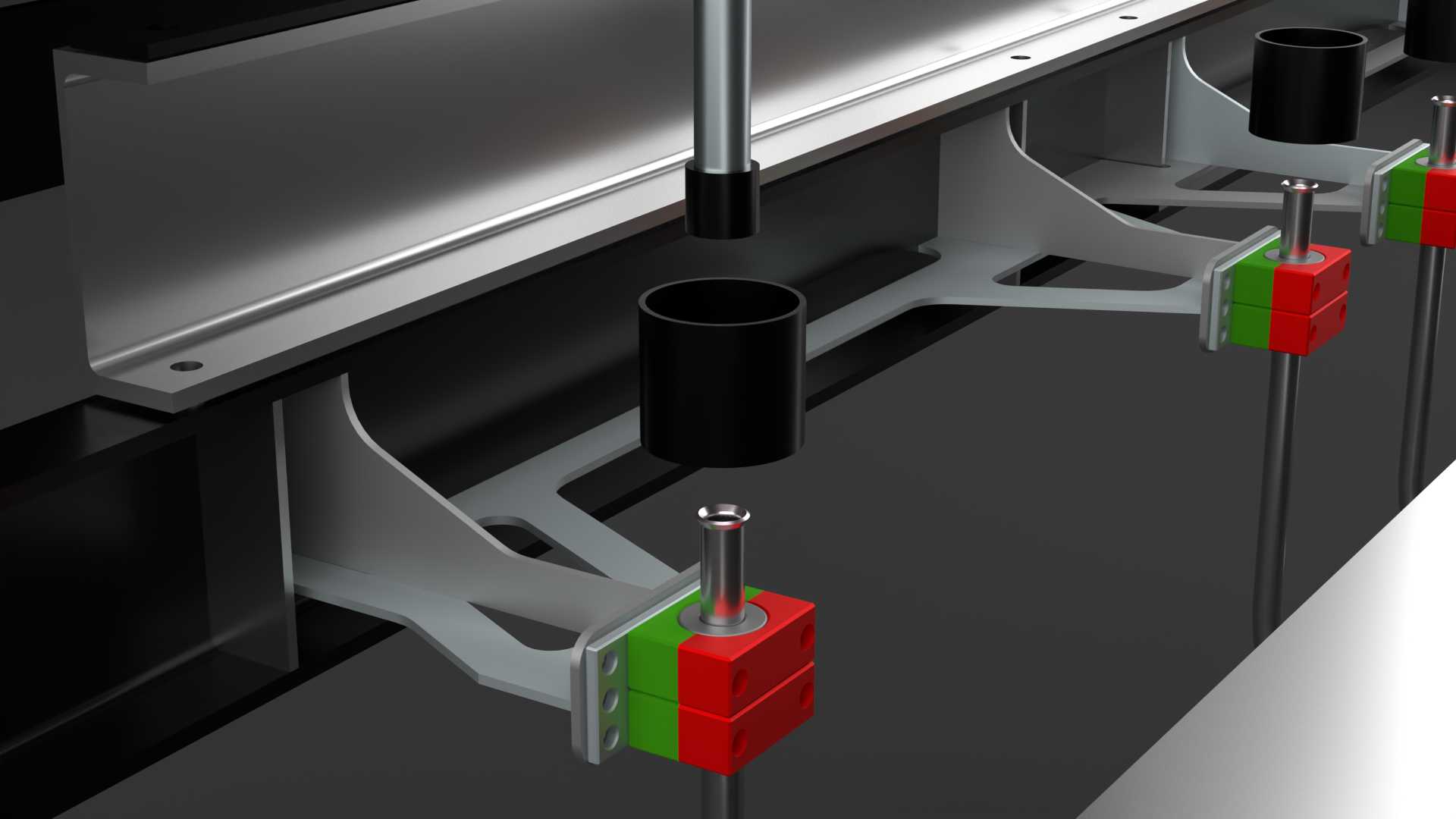

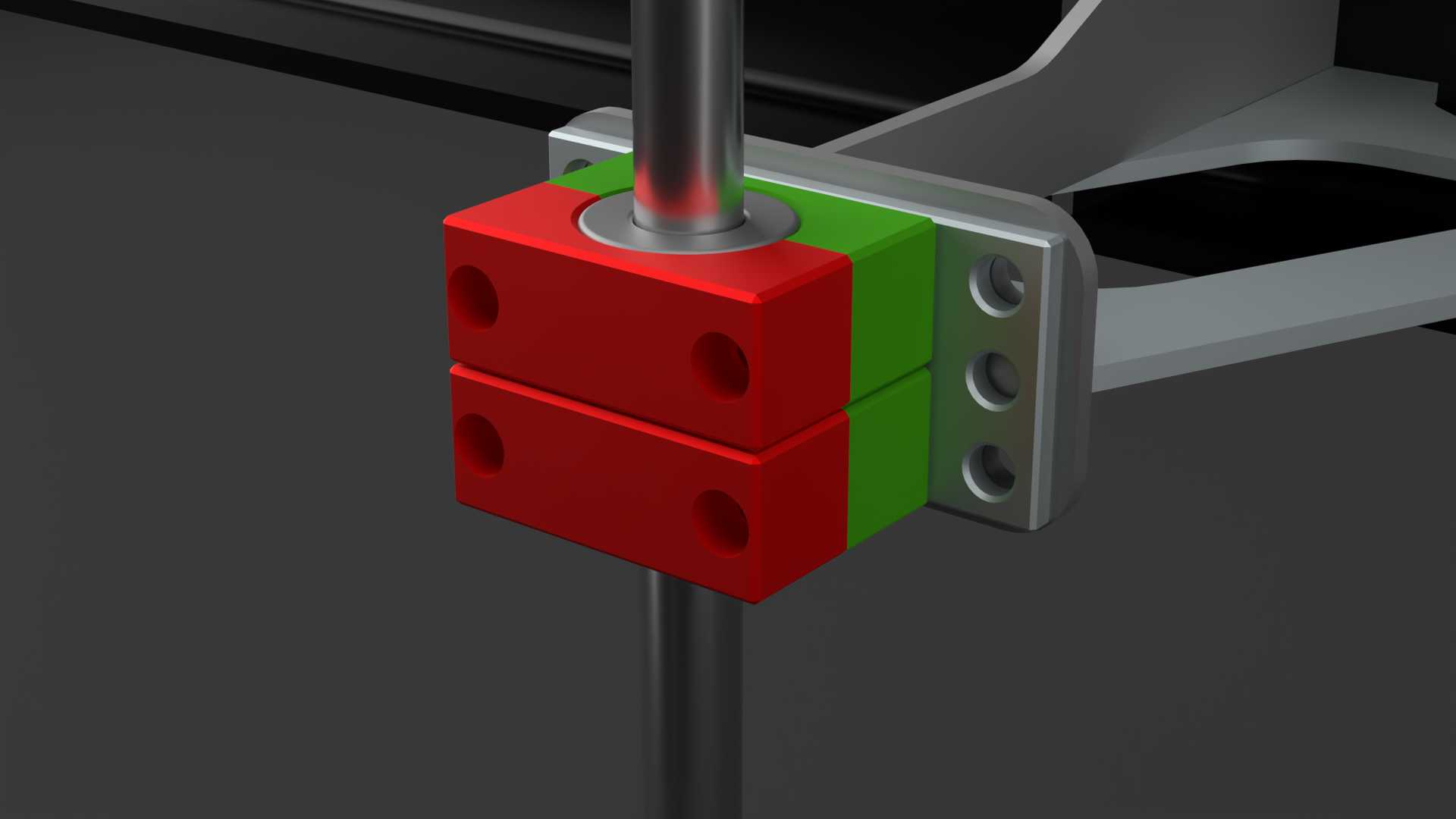

(Stauff clamps view 1)

(View 2)

Accomplishments

The high platform low vibration design successfully improved the durability of the cooler and this same design is now being rolled out to Kings Valley in the Solomon Hub.

(3D Viewer - Not added yet)

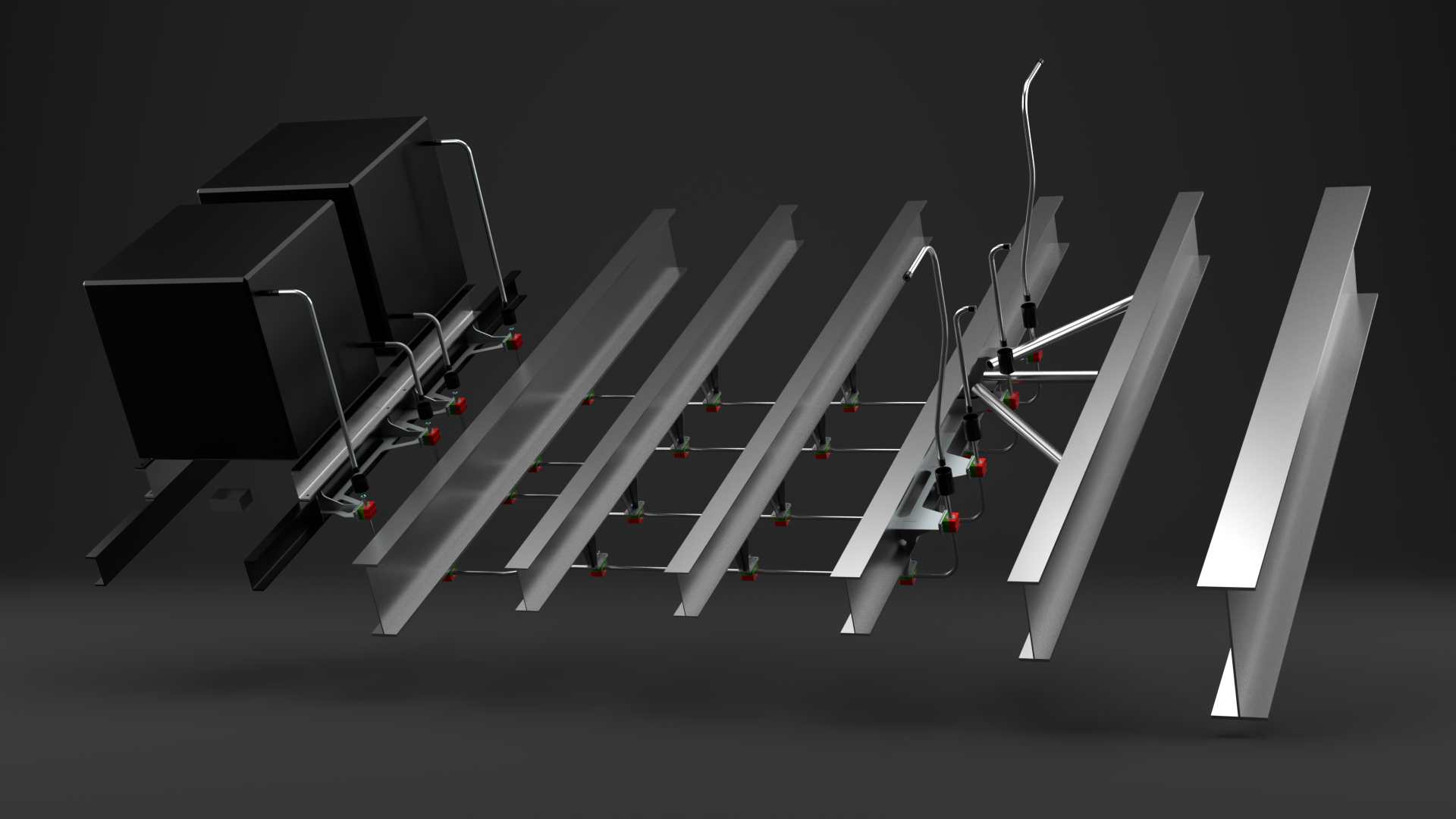

(Below - Custom pipe design)

(Top view)

(Close up)

Other projects

Coming Soon

...

Coming Soon

...