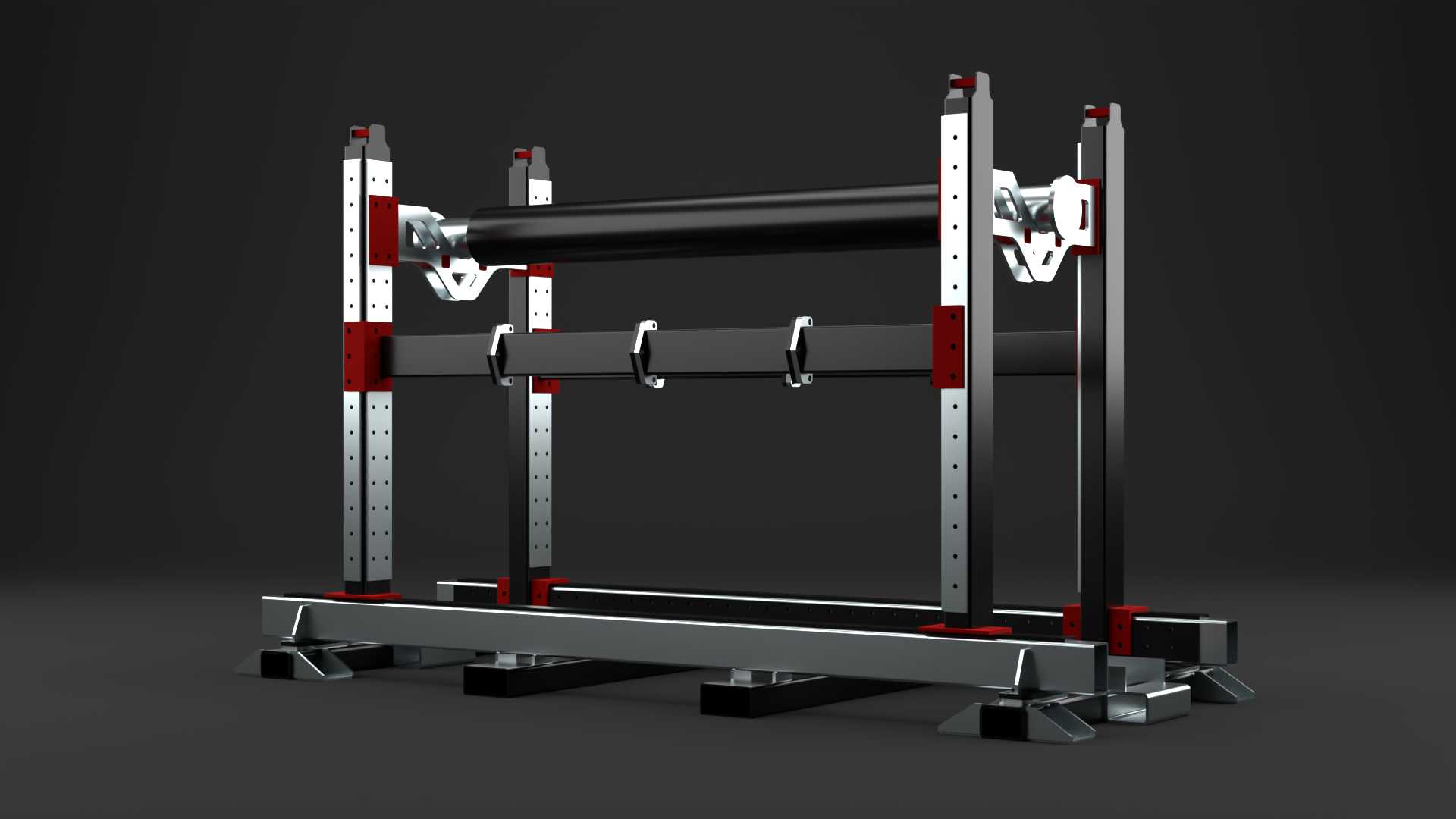

Platform Trolley Structure

Background

There was an incident in Kings Valley where the incorrect use of tools caused a set of isolation gates carried on pallet jacks (maximum weight of 3.6 tonnes) to tip over which damaged components of a conveyor belt.

It caused a tools down investigation and evaluation leading to the need for a new isolation gate design.

Scope of Work

During shutdowns there is the potential for large sections of ore that is stuck/piled up to avalanche through the chute and cause a potential loss of life. Without anything blocking the exit of the chute, any form of vibration or interference around the chute creates an extremely high risk. Some areas of the mine site, specifically at heights, were inaccessible to the previous isolation gate.

Objectives

- Design an isolation gate that is safe, highly maneuverable and can be moved to various heights.

Challenges Involved

The design was constrained to a maximum weight of 2.5 tonnes and required following the rules and regulations of Australian Standards 4100 and Australian Standards 4991 Lifting Devices.

Innovative Thinking

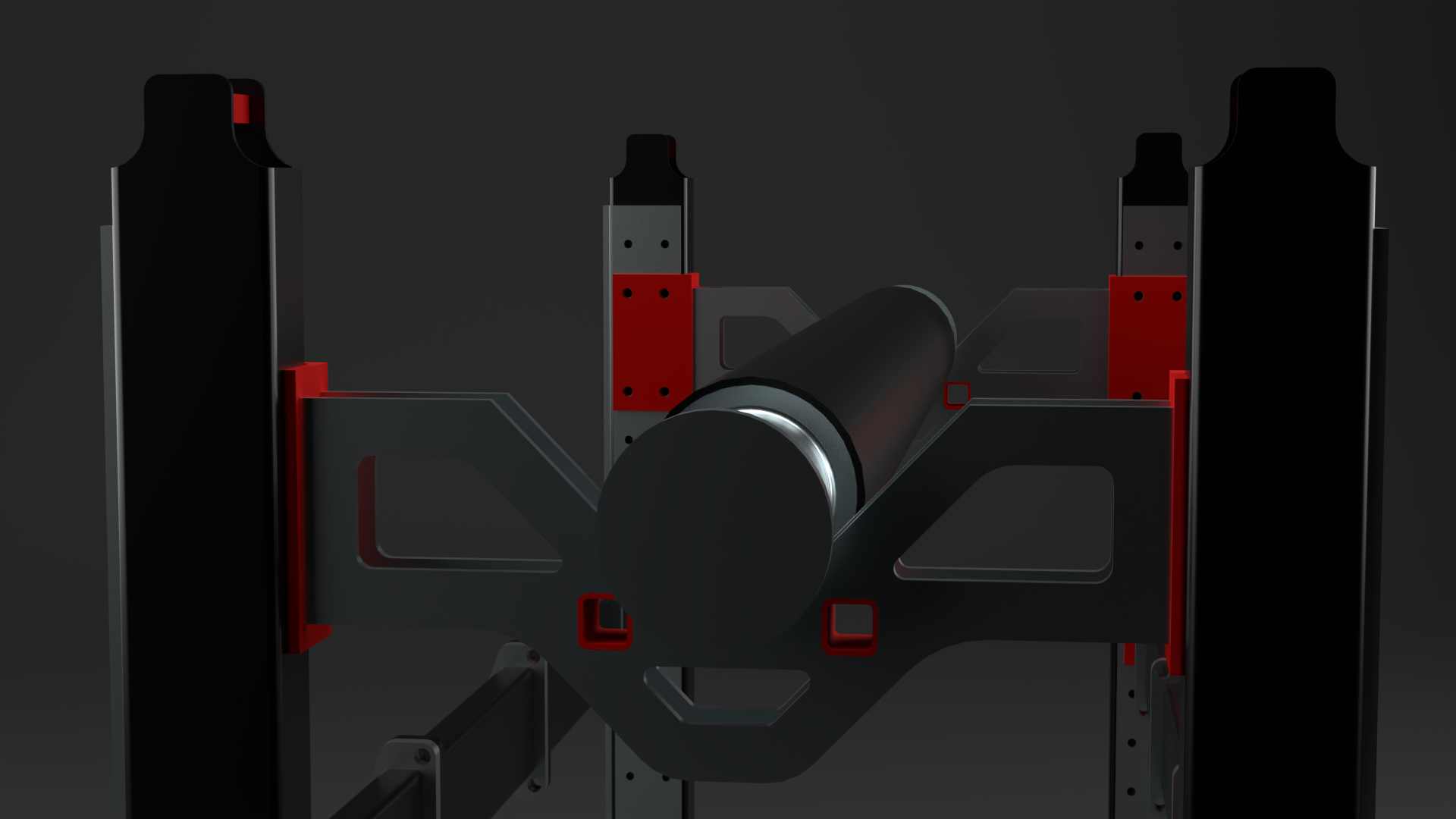

A flood gate style barrier was created to block off potential avalanching ore.

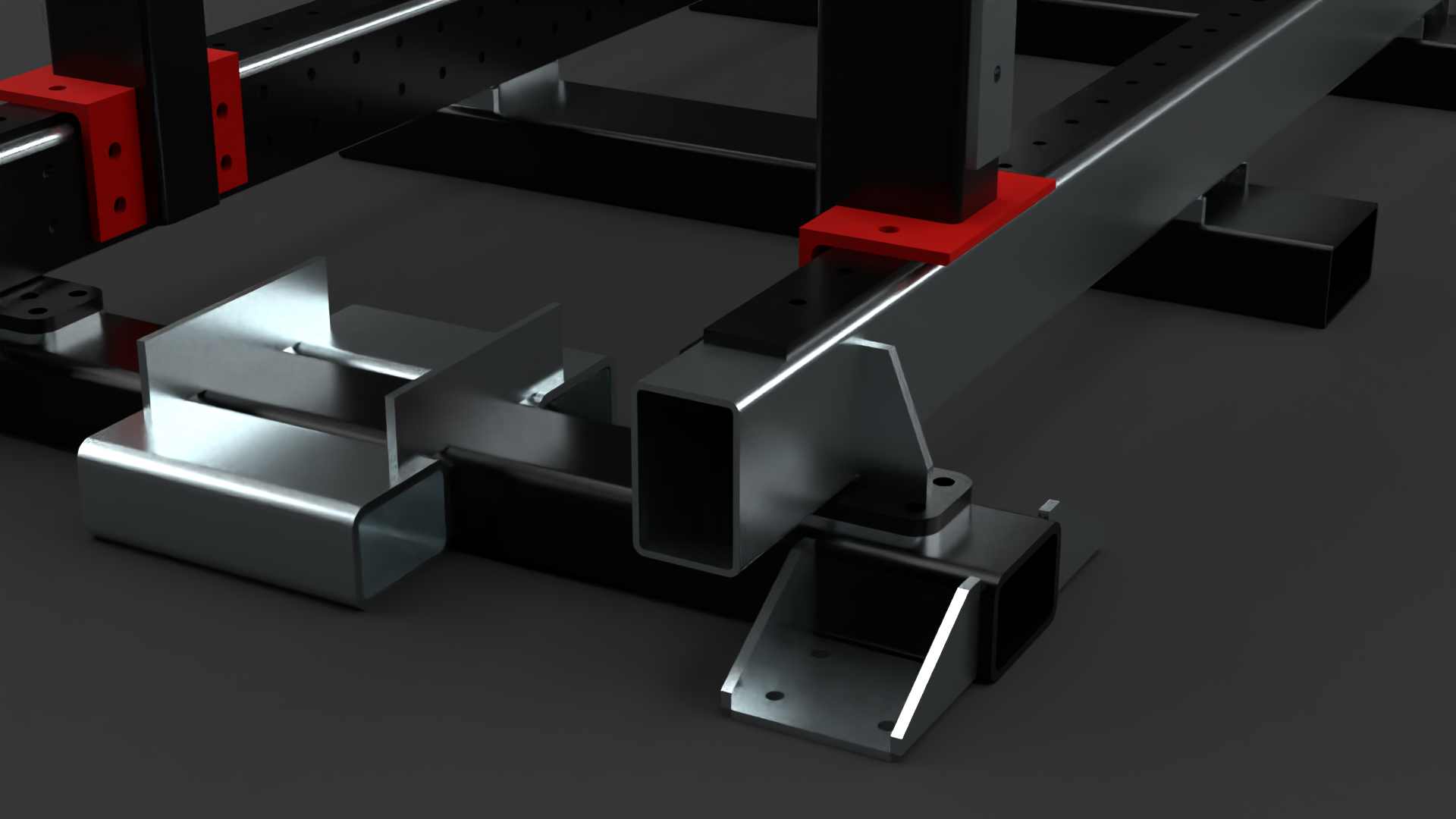

The model is designed so that a forklift can pick it up from the base and move it under a bin.

Additionally, it can be locked at four points to remove horizontal/vertical swinging when lifted up by a crane to be taken to higher platforms.

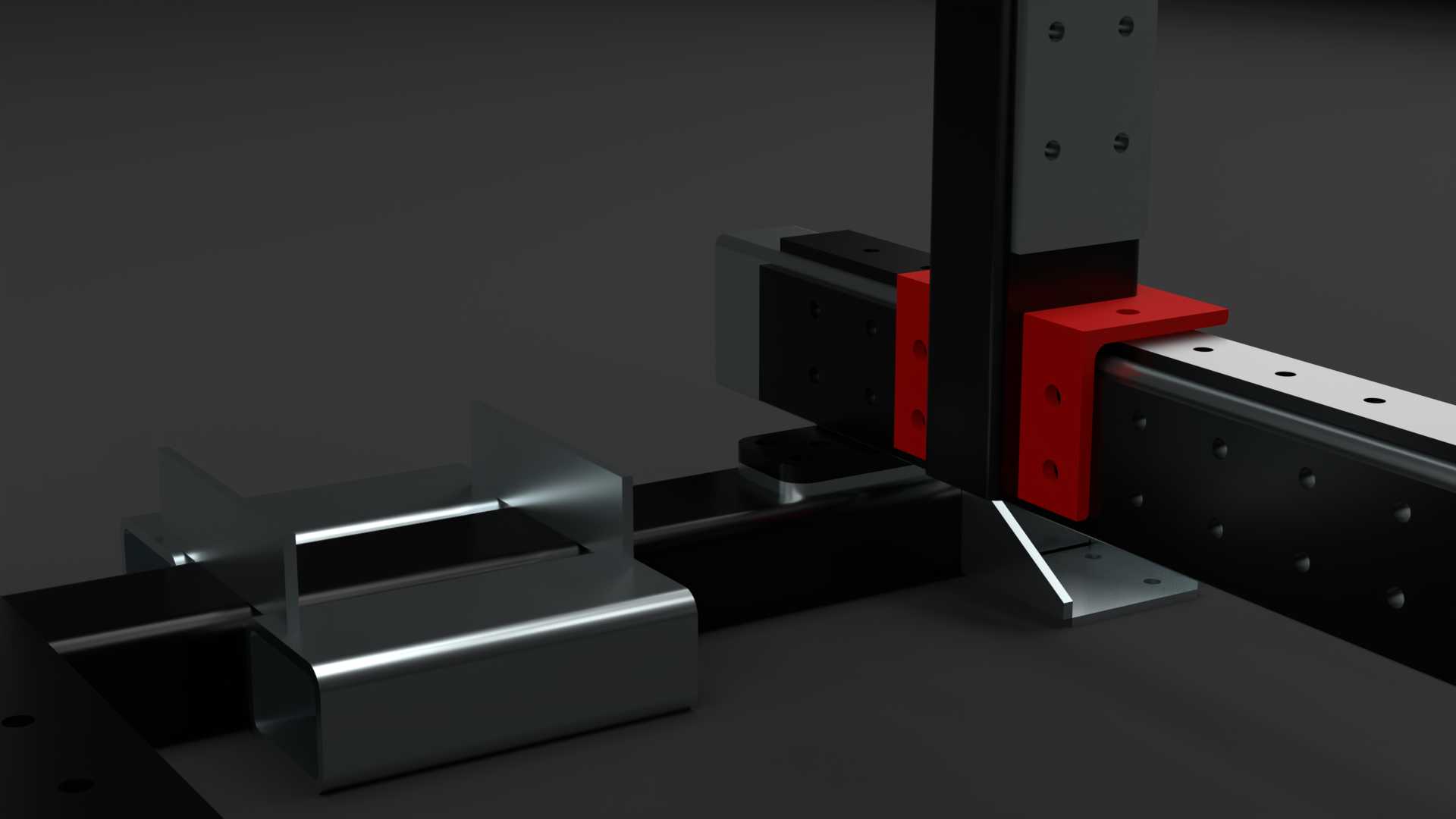

Included with heavy duty dolly wheels that allow it to roll over the 32mm steel platform gaps into position and be locked down safely to prevent potential high risk circumstances.

Accomplishments

The model was completed in two days.

The new design included a variety of applications and maneuverability into intricate confined spaces.

Maintenance teams can now access new areas of machinery that were previously deemed unsafe.

(3D Viewer - Not added yet)

(Platform Trolley - close up)

(Isometric close up)

(Alternative close up)

Other projects

Coming Soon

...

Coming Soon

...